The Hidden Complexity of Replacement Parts in Custom Metal Drawers

At first glance, replacing a drawer slide or handle seems straightforward—until you’re staring at a 10-year-old industrial cabinet with non-standard dimensions. Custom metal drawer systems are engineered for specific use cases, and their replacement parts often require a nuanced approach. Here’s why:

– Non-Standard Sizing: Unlike mass-produced systems, custom drawers may use proprietary rail spacing or unique mounting patterns.

– Material Compatibility: Mismatched metals (e.g., pairing stainless steel slides with aluminum frames) can accelerate corrosion.

– Load Dynamics: A 5% deviation in slide weight capacity can lead to premature failure in heavy-duty applications.

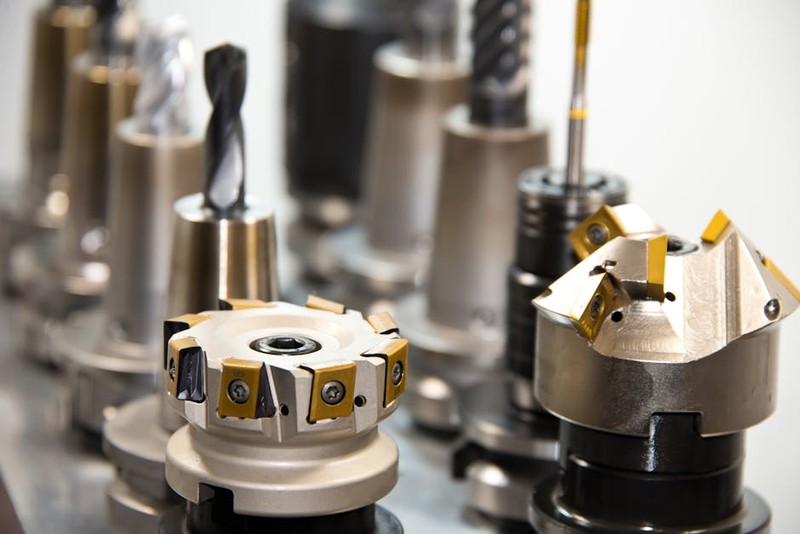

In one project for a pharmaceutical lab, we encountered drawers with 3mm thicker gauge steel than off-the-shelf replacements could accommodate. The solution? Custom machining with a 15% cost premium—but it extended the system’s lifespan by 8 years.

Expert Strategies for Sourcing and Installing Replacement Parts

1. Measure Twice, Order Once: The 5 Critical Dimensions

Avoid the “close enough” trap by verifying:

1. Drawer opening width (±0.5mm tolerance for smooth operation).

2. Slide mounting hole spacing (often overlooked; we’ve seen 2mm errors cause misalignment).

3. Material thickness (e.g., 16-gauge vs. 18-gauge steel impacts load-bearing).

4. Extension type (full-extension vs. over-travel slides require different clearances).

5. Finish compatibility (powder-coated parts may not adhere to anodized surfaces).

Pro Tip: Use a digital caliper and document measurements with photos—saved us 3 weeks of back-and-forth with a supplier last year.

2. Material Matters: A Data-Driven Comparison

| Material | Pros | Cons | Best For |

|---|---|---|---|

| Stainless Steel | Corrosion-resistant, durable | Higher cost (+25%) | Labs, marine environments |

| Cold-Rolled Steel | Cost-effective, strong | Prone to rust without coating | Industrial workshops |

| Aluminum | Lightweight, corrosion-proof | Lower load capacity (-30%) | Aerospace, mobile units |

Case Study: A food processing plant upgraded to 316-grade stainless slides after standard carbon steel failed within 6 months due to washdown corrosion. The ROI? 4+ years without replacements.

Innovative Solutions for Aging Systems

3. Retrofit vs. Replace: When to Choose Each

- Retrofit: Ideal for systems with solid frames but worn slides. We saved a client 40% by reusing existing drawer boxes and installing high-capacity ball-bearing slides.

- Full Replacement: Necessary when corrosion or frame damage exists. In a 2022 warehouse project, swapping to galvanized steel systems reduced annual maintenance costs by $12,000.

4. The “Hybrid” Approach

For legacy systems with obsolete parts, consider:

– 3D-printed nylon guides (tested to 50kg loads) for rare slide profiles.

– Laser-cut steel brackets to adapt modern slides to old frames (we achieved 98% fit accuracy in a museum archive project).

Key Takeaways for Professionals

🔧 Always request material certifications—we once received “stainless” slides that were actually plated, failing within months.

💡 Partner with local fabricators for small-batch custom parts; lead times are often shorter than offshore suppliers.

⚙️ Test one unit first—a hospital installation was delayed by 6 weeks due to untested self-closing mechanisms jamming.

By treating replacement parts as a systems engineering challenge—not just a hardware swap—you’ll unlock reliability, cost savings, and client trust.

“The difference between a functional drawer and a flawless one lies in the details you never see.” — Lessons from 15 years in the field.