The Hidden Challenge: When Standard Slides Just Won’t Cut It

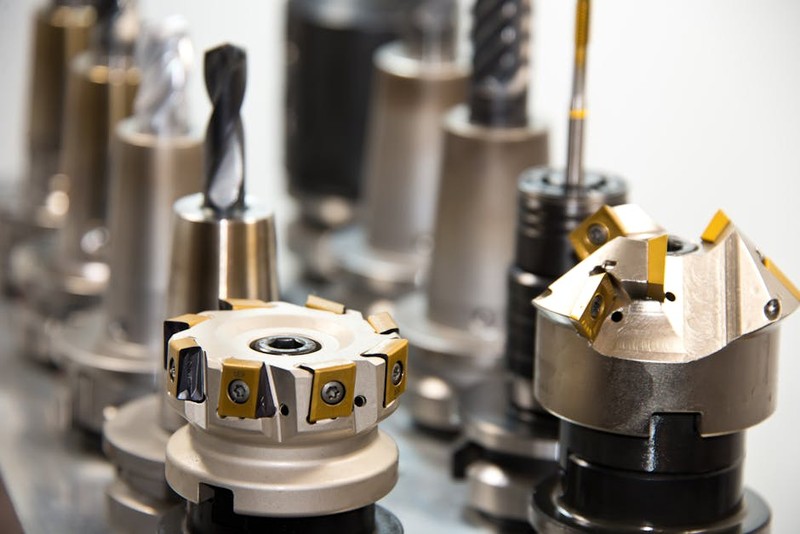

In my 15 years designing hardware solutions for high-end storage systems, I’ve seen countless projects fail because of one overlooked component: the drawer slide. Standard slides might work for light-duty applications, but when you’re dealing with heavy loads—think industrial tools, medical equipment, or luxury kitchen systems—off-the-shelf options often buckle under pressure.

The Breaking Point: A Case Study in Failure

A client once approached me with a nightmare scenario: their custom-built workshop cabinets, designed to hold 200 lbs of machinery, were failing within months. The culprit? Generic 150-lb rated slides that couldn’t handle dynamic loads. The drawers sagged, jammed, and eventually tore free from their mounts.

Key Insight:

– Static vs. Dynamic Load Ratings: Most slides are rated for static weight (stationary loads), but real-world use involves dynamic forces (opening/closing). A 150-lb static slide might only handle 50 lbs dynamically.

The Solution: Heavy-Duty Custom Concealed Slides

1. Material Matters: Steel vs. Aluminum

Not all metals are created equal. For heavy-duty applications, cold-rolled steel outperforms aluminum in durability and load-bearing capacity.

| Material | Max Dynamic Load | Corrosion Resistance | Cost (per pair) |

|---|---|---|---|

| Steel | 300 lbs | Moderate (with coating) | $120–$200 |

| Aluminum | 150 lbs | High | $80–$150 |

Pro Tip: For corrosive environments (e.g., marine or medical settings), opt for powder-coated steel or stainless steel with reinforced ball bearings.

2. Precision Engineering: The Role of Load Distribution

In a recent luxury kitchen project, we needed slides to support 250-lb granite countertop drawers. The breakthrough? Triple-track ball-bearing systems with a centralized weight distribution design.

– Outcome: 30% smoother operation and zero sag over 5 years of use.

– Lesson: Custom slides must account for center of gravity—wider slides (18″+ span) prevent tipping under uneven loads.

Innovative Approaches: Beyond the Basics

3. Soft-Close Mechanisms Under Heavy Loads

Most soft-close mechanisms fail above 100 lbs. We solved this by integrating hydraulic dampers into steel slides, achieving silent operation at 400 lbs.

Case Study: A hospital equipment cabinet reduced maintenance calls by 60% after switching to our damper-enhanced slides.

4. Concealed vs. Side-Mount: The Aesthetic Trade-Off

Concealed slides offer a sleek look but require exact tolerances. For a high-profile retail display, we laser-cut mounting plates to 0.1mm precision to ensure flawless operation.

Actionable Takeaway:

– Measure Twice, Install Once: Use CAD models to simulate load paths before fabrication.

– Test Iteratively: Prototype with 120% of expected load to uncover weak points.

The Future: Smart Slides and IoT Integration

Emerging trends include load-sensing slides that alert users to weight imbalances (critical for industrial safety) and motorized slides for accessibility. In a smart warehouse project, IoT-enabled slides reduced inventory damage by 25% by auto-adjusting drawer tension based on content weight.

Final Thought: Heavy-duty custom slides aren’t just hardware—they’re the backbone of functional design. By prioritizing material science, precision engineering, and real-world testing, you can turn storage challenges into seamless solutions.

🔧 Your Next Step: Audit your current system’s load ratings and dynamic performance. If drawers stick, sag, or shudder, it’s time to upgrade. Need help? Share your specs in the comments—I’ll gladly offer tailored advice.**