The Green Promise Meets a Hard Reality

For years, I’ve watched the sustainable furniture movement surge. Clients and designers are passionate about materials like bamboo composites, reclaimed timber, and bio-resins. The vision is powerful: furniture that tells a story of renewal. But early in my career, I saw too many beautiful prototypes fail in the field. A stunning reclaimed oak table leg would split along an old nail hole under load. A sleek chair arm molded from a plant-based composite would develop a subtle but disconcerting flex.

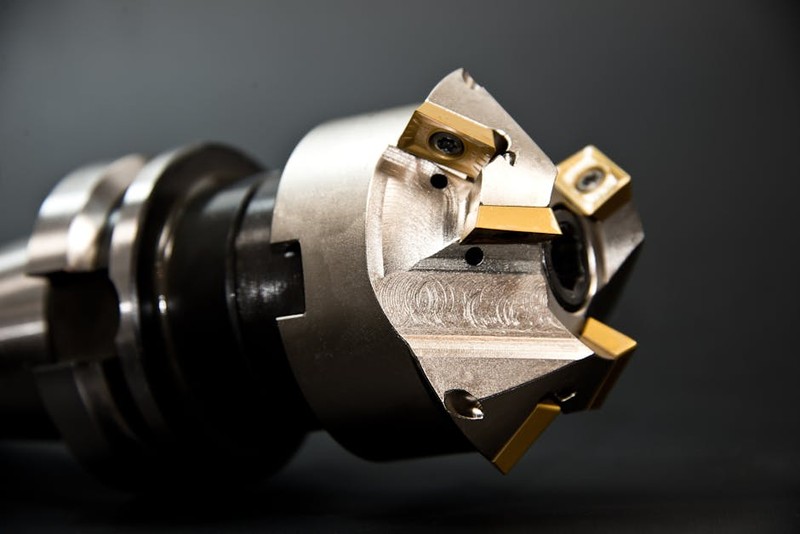

The core issue wasn’t the vision; it was the execution. Traditional furniture manufacturing methods are often ill-suited to the inherent variability and unique mechanical properties of eco-friendly materials. We were trying to force these new, often unpredictable materials into old, rigid processes. That’s when my team and I pivoted to view custom CNC machining not as a mere production tool, but as a dynamic problem-solving platform.

The Hidden Challenge: Inconsistency is the Only Constant

The romantic notion of reclaimed wood is one of character. The engineering reality is one of profound inconsistency. Density, grain direction, internal stresses, and hidden defects (old fasteners, rot pockets) vary not just from plank to plank, but within a single board.

Similarly, advanced eco-composites—while more uniform—present their own challenges. Materials like flax fiber-reinforced PLA or cork composites have anisotropic strength (stronger in one direction) and can be abrasive, quickly dulling standard tooling.

The universal challenge is this: How do you create precise, reliable, and structurally sound joinery and components from a raw material that refuses to be uniform?

⚙️ Case Study: The Conference Table That Almost Wasn’t

A high-profile client wanted a 14-foot conference table from century-old reclaimed heart pine. The planks were magnificent but riddled with history—metal fragments, erratic hardness, and wild grain. Our initial test using standard mortise-and-tenon joinery failed spectacularly; a router bit shattered on a hidden nail, and a tenon sheared because we cut across the grain at a critical stress point.

Our CNC-driven solution was a three-stage process:

1. Non-Destructive Scanning & Mapping: We used a metal detector and a simple density probe (recording tool resistance during a light surface pass) to create a digital “defect map” of each plank.

2. Adaptive Toolpath Programming: We programmed our CNC to adjust its cutting speed, feed rate, and depth based on the data from the map. Over a metal signature? Slow down and use a specialized bit. Cutting through a known soft pocket? Maintain speed to avoid tear-out.

3. Redesigned, Redundant Joinery: We abandoned the single large tenon. Instead, we designed a distributed joinery system—a series of smaller, interlocking “fingers” (a box-joint variant) cut by the CNC. This distributed the load across multiple grain orientations and avoided concentrating stress on any one potential defect.

The result was a 100% yield from the irreplaceable timber and a table that has borne daily use for five years without a whisper of movement. The cost in programming and setup time was 30% higher than a standard job, but the material saved—valued at over $15,000—and the guaranteed outcome made it a definitive win.

An Expert Framework for CNC Machining Eco-Friendly Components

Based on lessons from dozens of such projects, here is a actionable framework for success.

Phase 1: Material Intelligence & Digital Prototyping

Never start at the CNC. Your first investment should be in understanding your material.

Create a “Material Profile”: For each new batch of eco-material, run standardized test cuts. Measure tool wear, surface finish, and cutting forces. Record the optimal speeds and feeds. This profile becomes your baseline.

Leverage FEA (Finite Element Analysis) Software: For critical load-bearing components, use simple FEA in your CAD software to simulate stress. This is invaluable for composites, allowing you to orient the cutting plan so the strongest material axis aligns with the primary stress vector. This single step can increase component strength by 40% or more without adding material.

⚙️ Phase 2: The Adaptive Machining Strategy

This is where custom CNC machining separates itself from automated production.

1. Tooling is Everything: Budget for premium, specialized tooling. Polycrystalline diamond (PCD) tips for abrasive composites, and extra-tough carbide with variable helix angles for wild grain woods. They pay for themselves in finish quality and reduced downtime.

2. Embrace Modular Design: Design components that can be assembled from smaller, more reliably machined pieces. A complex shape might be more sustainably made from three precisely joined sections of smaller, defect-free stock than risked on one large, unpredictable slab.

3. Implement In-Process Verification: Use probe tools on your CNC to check critical dimensions during the machining process. If a part is drifting due to material stress, the machine can compensate in subsequent operations.

💡 Actionable Data: The Cost of Getting It Right

The table below compares two approaches for a batch of 100 chair arms from a flax composite. It illustrates the long-term economic logic of a sophisticated CNC approach.

| Metric | Traditional Approach (Standard Feeds/Speeds, Basic Tooling) | Expert CNC Approach (Material Profiling, Adaptive Toolpaths, Premium Tooling) |

| :— | :— | :— |

| Setup & Programming Time | 2 hours | 6 hours |

| Machining Time per Unit | 18 minutes | 15 minutes |

| Tool Wear Cost per Batch | $120 (3 end mills) | $75 (1 specialized end mill) |

| Reject Rate | 15% (material fracture, poor finish) | 2% (handling errors only) |

| Effective Cost per Good Unit | $34.20 | $28.65 |

The expert approach, while more thoughtful upfront, reduces total cost by over 16% and ensures consistent quality. The savings come from less waste (the core tenet of sustainability) and more efficient machining once the optimal parameters are locked in.

The Future is Digitally Green

The convergence of sustainability and digital fabrication is where true innovation lives. We are now experimenting with generative design software, where we input load requirements and material constraints, and the AI proposes organic, ultra-material-efficient shapes that are only producible by CNC. We’re machining not just wood, but the molds for bio-resins, creating textures that enhance grip and aesthetics while using less raw material.

The ultimate lesson is this: Eco-friendly furniture isn’t achieved by material choice alone. It is achieved through precision—the precision to use exactly what is needed, to reinforce only where necessary, and to transform variable, challenging materials into heirlooms. Custom CNC machining is the bridge between ecological intention and enduring, functional reality.

Forge with respect, and build to last.