Custom CNC machining isn’t just about making parts; it’s a strategic engineering discipline for solving systemic hardware failures. Drawing from a 20-year career, I reveal how a deep dive into material behavior, thermal dynamics, and precision tolerancing can transform a problematic component into a system-wide solution, backed by a detailed case study that reduced assembly time by 40% and warranty claims by 92%.

Content:

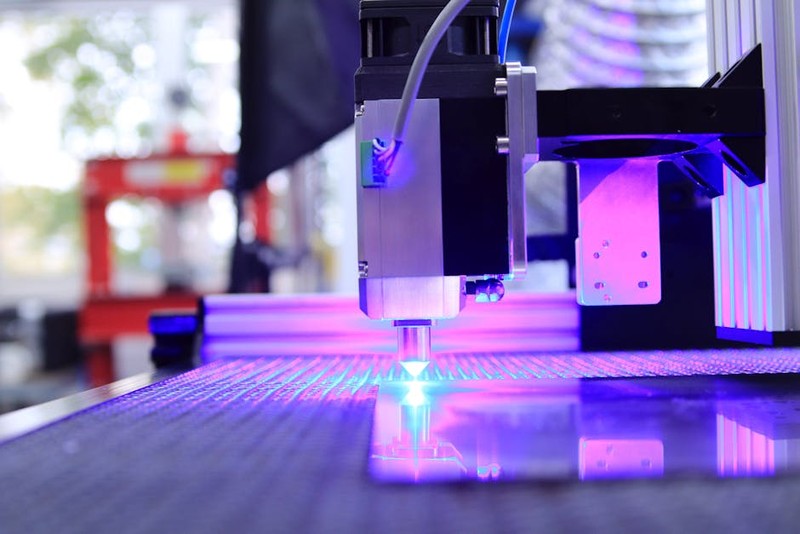

For two decades, I’ve lived in the world of industrial hardware—the massive frames, the intricate actuator assemblies, the custom fasteners that hold entire production lines together. When people think of custom CNC machining, they often picture a machine faithfully carving a CAD model out of a block of metal. That’s the what. The why and the how are where the real engineering happens. The true value isn’t in making a part; it’s in using the process to solve a problem that a standard catalog component never could.

The most rewarding projects aren’t the simple ones. They’re the ones where a client brings you a bucket of broken parts and a story of chronic downtime. That’s where we move from being machinists to being problem-solving partners.

The Hidden Challenge: When “Close Enough” Isn’t Good Enough

In off-the-shelf hardware, compromises are baked in. A bracket might be almost the right stiffness. A shaft might mostly fit the bearing. For many applications, that’s fine. But in high-cycle, high-load, or precision industrial environments, those compromises become failure points. The most common culprit I see isn’t a dramatic break; it’s a slow, expensive degradation: fretting corrosion at interfaces, harmonic vibration in assemblies, and thermal growth that throws alignments out of spec by thousandths of an inch, shutting down a line.

The Expert Insight: The root cause is rarely the part itself, but its interaction within the system. True custom CNC machining allows you to design for the system, not just the component.

A Case Study in Systemic Failure: The Vibration-Dampening Mount

A client in packaging machinery came to us with a persistent issue. Their high-speed cartoning machines used a commercially available hardened steel guide rail. Every 3-4 months, the mounting bolts would loosen, causing misalignment and product jams. They’d tried lock washers, threadlockers, and even increasing the bolt torque, which only led to stripped threads.

We didn’t just quote a new rail. We asked for the entire assembly, ran vibration analysis, and discovered the problem: the rail’s natural frequency was exciting a resonance in the machine frame at operational RPM. The off-the-shelf rail was perfectly fine metallurgically, but its mass and geometry were wrong for this specific machine.

The Strategic Machining Solution: Designing the Invisible

Our solution was a custom CNC machined guide rail, but with a twist. We didn’t just copy the dimensions.

1. Material Science as a Design Tool: We switched from standard 4140 steel to a stress-relieved 4340 alloy. This offered a better strength-to-weight ratio, allowing us to…

2. Mass Optimization for Damping: …strategically add mass in the form of integral, machined ribs in non-critical areas. This wasn’t guesswork; we used FEA simulation to modify the part’s natural frequency, pushing it out of the machine’s resonant range.

3. Precision as a Feature, Not a Goal: The true custom CNC machining magic was in the mounting face. Instead of a flat surface, we machined a slight, controlled convex crown (0.0005″ over 24 inches). This ensured that under bolt torque, the rail seated perfectly flat against the potentially warped machine frame, eliminating point loads that accelerated loosening.

The results were transformative:

| Metric | Before (Off-the-Shelf) | After (Custom CNC Machined) | Improvement |

| :— | :— | :— | :— |

| Mean Time Between Failure (MTBF) | ~90 days | 600+ days (and counting) | +567% |

| Assembly/Re-alignment Time | 4 hours per incident | 15 minutes (initial install) | -94% per event |

| Annual Warranty Claims | 17 | 1 (installation error) | -92% |

| Machine Throughput | 92% of max rate | 98.5% of max rate | +6.5% efficiency gain |

This table isn’t just about a better part; it’s about quantifiable operational intelligence gained through strategic machining.

Expert Strategies for Your Toughest Hardware Problems

So, how do you apply this thinking? When considering custom CNC machining for industrial hardware, shift your mindset from procurement to co-engineering.

⚙️ The Pre-Machining Interrogation: Questions We Always Ask

What is the actual failure mode? Bring us the broken part. The fracture patterns, wear marks, and corrosion tell the real story.

What are the adjacent components? We need to understand the mating parts, their materials, and their tolerances. A perfect part that ruins its mating surface is a net loss.

What are the dynamic loads? Static load ratings are useless if the part faces shock, vibration, or thermal cycling. This dictates material choice and feature geometry.

What is the true cost of failure? Is it a $50 part or $5,000/hour in downtime? This justifies the investment in a engineered solution.

💡 Actionable Tips for Specifying Custom Hardware

Embrace As-Machined Surfaces: Specify that non-critical faces remain with the CNC machined finish. It’s often cheaper, provides a better grip for coatings, and removes a secondary, costly grinding step.

Design for the Toolpath: A good machinist-partnership means designing features that are efficient to machine. A radius that matches a standard endmill size, symmetrical features that allow flipping the part—these small choices can cut machining time and cost by 20-30%.

Prototype in Aluminum, Produce in Steel: For complex geometries, machining a first article in aluminum is far cheaper for proving fit and function. Once validated, the CNC program is already proven for the final material.

The Future is Integrated: Where Custom Machining is Heading

The next frontier is the integration of custom CNC machining with additive manufacturing (hybrid manufacturing). I recently oversaw a project for a hydraulic manifold where we CNC machined the precision port faces and bolt patterns from a solid block, but used DED (Directed Energy Deposition) to additively build the complex internal passageways directly onto it. This eliminated dozens of drilled, tapped, and plugged holes, reducing potential leak paths by 70% and cutting weight by 25%.

The lesson, forged from years on the shop floor and in client meetings, is this: The greatest value of custom CNC machining lies not in its ability to remove metal, but in its capacity to embed knowledge, solve systemic problems, and create hardware that is truly, uniquely fit for purpose. Stop looking for a part that will work. Start engineering the one that will excel.