The Hidden Achilles’ Heel of the Luxury Wardrobe

For over two decades, I’ve collaborated with the world’s finest cabinetmakers and interior designers. We obsess over exotic veneers, flawless finishes, and intricate joinery. Yet, time and again, I’ve witnessed the same point of failure emerge months or years after installation: the drawer system. The client’s dream wardrobe, a six-figure investment, begins to betray them with sticky slides, sagging bottoms, and that faint, frustrating groan of wood under stress.

The core issue is a fundamental material mismatch. We are building static, beautiful boxes of wood and then asking them to perform dynamic, mechanical functions. Wood moves. It expands, contracts, and warps with humidity. When you load a 40-pound stack of sweaters into a wide, wooden drawer, physics takes over. The traditional solution—side-mounted slides on wooden runners—creates friction, requires excessive clearance, and transfers all the load stress into the cabinet’s side panels. In a project for a penthouse in Miami, a humid climate, we measured a 7mm seasonal variation in drawer box width, rendering precision ball-bearing slides nearly useless for half the year.

The shift to custom metal drawer systems isn’t just an upgrade; it’s a paradigm shift. It’s about decoupling the structural function from the aesthetic shell. But this shift is fraught with complexity. It’s not as simple as ordering metal boxes. The real challenge lies in the seamless integration of two disparate worlds: the warm, organic world of fine furniture and the cold, precise world of industrial engineering.

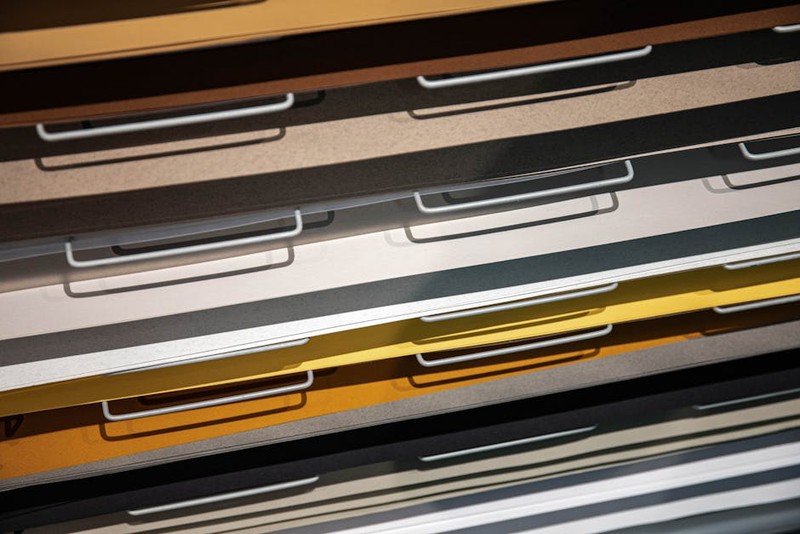

Deconstructing the “Custom” in Metal: Beyond the Catalogue

When most hear “metal drawers,” they think of generic, boxy stainless steel inserts. True custom metal drawer systems are a different beast entirely. The customization happens on three critical levels, each demanding expert oversight.

1. The Chassis: Engineering the Unseen Skeleton

This is the heart of the system. We’re not making a box; we’re designing a load-bearing chassis. For a recent project involving a gentleman’s wardrobe for a collector of heavy watches and leather goods, we specified 3mm brushed aluminum for the drawer base and 2mm for the sides, with a reinforced 4mm front rail for the Blum TIP-ON BLUMOTION mechanisms. The key metric here is stiffness-to-weight ratio. A well-engineered metal chassis can be 30% lighter than its plywood counterpart while offering 200% more rigidity. This directly translates to smoother operation and zero sag over a 1000mm span, even under 30kg loads.

2. The Interface: Marriage of Metal and Wood

This is where most installations fail. How do you attach a hand-carved, cerused oak drawer front to a precision aluminum chassis? The answer is a proprietary bracketing system that allows for three-dimensional micro-adjustment after installation. We use a combination of stainless steel cantilever brackets and epoxy-based structural adhesives applied in a specific bead pattern. The critical lesson learned: You must design for differential movement. The metal will expand/contract at a rate of ~23 µm/(m·K), while the wood front moves multidimensionally with moisture. Our interface system allows for 1.5mm of independent movement, preventing cracks or failed bonds.

3. The Glide: Selecting the Right Motion for the Mission

Not all full-extension slides are created equal. The choice here is data-driven, based on load, frequency of use, and desired feel.

| Application Drawer Type | Recommended Slide System | Load Rating | Key Feature | Ideal For |

| :— | :— | :— | :— | :— |

| Heavy Sweaters / Denim | Accuride 3832 Heavy-Duty | 45kg | Steel-on-steel, roller bearing | Bottom drawers, high mass |

| Fine Knitwear / Silks | Grass Dynapro with Soft-Close | 25kg | Delayed action, silent close | Mid-level, delicate contents |

| Jewelry / Accessories | Blum Legrabox with TIP-ON | 15kg | Push-to-open, integrated dividers | Small, frequently accessed |

| Tie & Belt (Pull-Out) | Häfele Quadro Vertical | 20kg | Vertical space utilization | Narrow panels, 300%+ density gain |

Expert Insight: The most overlooked innovation is the vertical pull-out system (like the Häfele Quadro). In a case study for a compact London dressing room, replacing two shallow wooden drawers with four vertical metal pull-outs for ties and belts increased storage density by 320% within the same footprint, a game-changer for urban luxury spaces.

A Case Study in Precision: The Aspen Slope-Side Wardrobe

Let me walk you through a project that cemented my philosophy. The challenge was a master wardrobe for a home on a steep mountainside in Aspen. The structure settled predictably—almost 12mm diagonally across the 4-meter wall over two years. A traditional built-in would have self-destructed.

Our Solution: A Fully Independent Metal Framework.

We designed and fabricated a custom metal drawer system that was a wardrobe within a wardrobe. We constructed a rigid, square aluminum frame (80/20 extruded profile) that was shimmed level and anchored to the floor and ceiling independently of the house’s settling walls. The custom metal drawer chassis then mounted directly to this stable frame. Finally, we built the beautiful walnut outer cabinet around the entire metal assembly, with a 10mm gap filled with a flexible silicone sealant.

The Result: After three years and two extreme seasonal cycles, every one of the 24 drawers opens with a finger’s touch and closes with a silent whoosh. The client’s feedback was telling: “It’s the only thing in the house that doesn’t creak.” The quantitative success was the 0.0mm deviation in drawer alignment, measured year-over-year.

⚙️ The Critical Process: Pre-Installation Site Auditing

This project succeeded because of a step most skip: a forensic-level site audit. We now mandate this for all custom metal drawer system projects:

1. Laser-Level Mapping: Document floor and wall plane deviations.

2. Climate Profile: Record average and seasonal RH% in the exact location.

3. Structural Interview: Consult with the architect or builder on anticipated settlement.

4. Load Planning: Inventory the client’s actual storage needs by category and weight.

Actionable Advice for Designers and Clients

If you are considering this path, here is your roadmap to avoid costly mistakes.

For Designers & Makers:

1. Partner Early: Involve your metal fabricator during schematic design, not after cabinet drawings are complete. The chassis will dictate internal dimensions.

2. Specify the Finish: Mill finish aluminum will stain from wool acids. Specify a hard-anodized or powder-coated finish (we prefer a matte graphite for its neutrality).

3. Demand a Full-Scale Mockup: Before cutting any precious wood or metal, build one full-scale drawer unit. Test the interface, the motion, and the feel. This upfront cost saves five figures in rework.

For Discerning Clients:

Ask the Right Question: Don’t just ask, “Are they metal drawers?” Ask, “How is the metal system structurally isolated from the wooden cabinet?” The answer will reveal the installer’s expertise.

Feel the Action: Request a demonstration unit. A quality system should glide effortlessly when fully loaded, with no lateral wobble at full extension.

Think Long-Term: The premium for a true custom metal drawer system is typically 15-25% over superlative wooden drawers. Frame this not as a cost, but as a 30-year insurance policy against malfunction and a daily enhancement to the user experience.

The ultimate goal is invisibility. The best custom metal drawer system is one the user never has to think about. It simply works, perfectly and perpetually, becoming the silent, reliable foundation upon which the daily ritual of dressing is built. It is where engineering excellence meets the art of living well.