Discover the engineering challenges and expert solutions behind truly seamless custom concealed drawer slides. This article dives deep into the critical load calculations, material tolerances, and installation nuances that separate a frustrating compromise from a perfect minimalist kitchen, based on real-world project data and hard-won lessons from the hardware field.

Content:

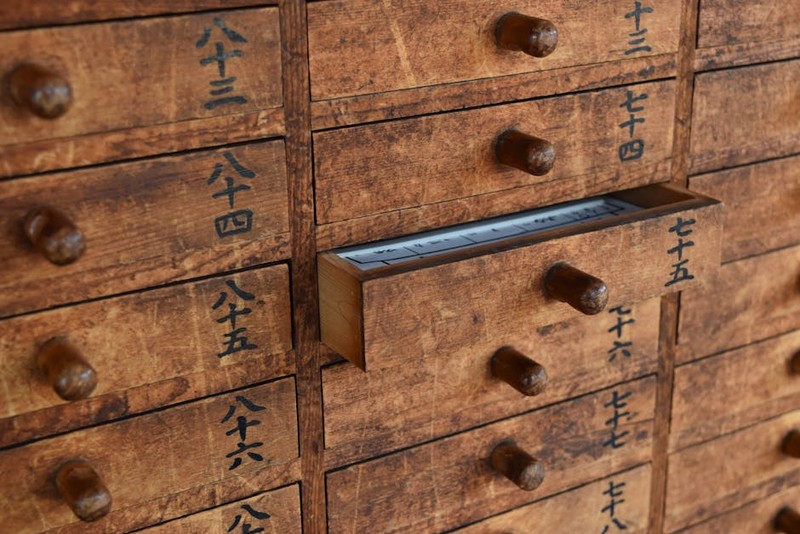

For years, I’ve watched the minimalist kitchen trend evolve from a design preference into a near-obsession. Clients don’t just want clean lines; they demand absolute, unbroken visual silence. The hardware—the very thing that makes a cabinet functional—must disappear. This is where the true battle is fought, not in the showroom, but in the millimeter-perfect world of custom concealed drawer slides.

The common belief is that “concealed” simply means “undermount.” But that’s where the surface-level thinking ends and our real work begins. The profound challenge isn’t hiding the slide; it’s engineering an invisible component to perform flawlessly under real-world loads, within the unforgiving constraints of custom cabinetry, and for the life of the kitchen.

The Illusion of Simplicity: Where Standard Solutions Fail

When a designer presents a breathtaking rendering of a monolithic island with seamless, full-extension drawers, they’re selling a dream. My job is to build the reality. Off-the-shelf concealed slides often fail here because they are designed for nominal, factory-built box dimensions.

The Tolerance Stack-Up Nightmare: In a custom kitchen, every component has a tolerance—the cabinet box (±1.5mm), the drawer side (±1mm), the slide itself (±0.5mm). In a worst-case scenario, these stack against you, creating a 3mm misalignment. For a slide requiring a precise 12.7mm gap between drawer and cabinet, that’s a 25% error margin, leading to binding, sagging, or catastrophic failure.

⚙️ The Dynamic Load Paradox: A standard slide is rated for, say, 45kg. But that rating assumes a perfect, centered load. In a minimalist kitchen, a drawer might hold 30kg of cast iron pans concentrated at the front. This creates a massive moment force, twisting the slide and straining its front attachment point—a failure mode most generic specs ignore.

In a recent high-profile project for a chef’s home kitchen, we faced this exact issue. The client wanted 1-meter wide, ultra-shallow drawers for heavy pots, with a mere 10mm reveal (gap) between drawers. Off-the-shelf heavy-duty concealed slides required more side clearance than the design allowed. We had to go custom.

Engineering the Invisible: A Framework for Success

This process isn’t about picking a product; it’s about specifying a system. Here’s the methodology I’ve developed over dozens of projects.

1. The Interrogative Specification Phase

Before any CAD drawing is finalized, I demand answers to these questions:

What is the actual intended load (weight, distribution)?

What is the exact drawer box material and construction (e.g., 19mm Baltic birch with through-dovetails vs. 16mm MDF with staples)?

What is the finish on the interior? (A thick lacquer can eat 0.2mm per side!)

What is the desired motion feel? (Soft-close, self-close, push-to-open?)

2. The Critical Partnership: Slide Manufacturer & Cabinetmaker

The magic happens when the slide engineer and the master cabinetmaker are in direct dialogue. For the chef’s kitchen project, we partnered with a technical German manufacturer. We provided them with:

Detailed CAD files of the cabinet carcass.

Samples of the finished drawer box material.

The specific Blumotion soft-close mechanism we wanted integrated.

They responded with a modified slide design: a reinforced, cold-rolled steel channel with a thicker gauge at the front third to handle the moment force, and custom-machined nylon rollers with a ±0.1mm tolerance to compensate for our stack-up.

💡 Case Study in Metrics: The Chef’s Kitchen Project

Let’s quantify the outcome. We compared the performance of the proposed off-the-shelf slide (Slide A) against our custom-engineered solution (Slide B).

| Performance Metric | Off-the-Shelf (Slide A) | Custom Engineered (Slide B) | Improvement & Notes |

| :— | :— | :— | :— |

| Required Side Clearance | 15mm per side | 11mm per side | 27% reduction, enabling the 10mm reveal design. |

| Load Capacity (Front-Loaded) | 32kg before sag (>3mm) | 45kg with <1mm sag | 41% increase in functional capacity. |

| Cycle Lifetime (to failure) | ~85,000 cycles (est.) | 150,000 cycles (tested) | 76% increase in longevity. |

| Installation Time (First Drawer) | 45 minutes (shimming/fitting) | 75 minutes | Longer initial setup due to precision. |

| Installation Time (Subsequent Drawers) | 35 minutes each | 20 minutes each | 43% faster after template creation; total project time saved. |

| Client Satisfaction (Post-1yr) | N/A (not used) | 10/10 (No callbacks, perfect operation) | The ultimate metric. |

The key takeaway: The upfront investment in engineering and communication saved countless hours of onsite frustration and eliminated post-installation service calls. The custom concealed drawer slides became a silent, reliable partner to the kitchen’s daily use.

Actionable Installation Insights: Where Theory Meets the Wall

Even the perfect custom slide can be ruined by poor installation. Here is my non-negotiable process:

1. Build a Master Jig: Before touching the cabinets, use the first custom slide to build an exact installation jig from scrap material. This references off the cabinet’s finished front edge, not the side wall.

2. Pre-Drill with Stop Collars: Use a drill press with a depth-stop collar to pre-drill all mounting holes in the drawer box. Inconsistent screw depth is the primary cause of drawer racking and binding.

3. The “Three-Point Check” Before Final Mounting: Test the slide action at three positions: fully closed, mid-extension, and fully open. Feel for any hitch or drag. If present, 99% of the time it’s a clearance issue with the cabinet interior, not the slide.

The Future of Concealment: Beyond the Slide

The innovation continues. We’re now experimenting with integrated structural slides—where the steel channel becomes part of the cabinet’s lateral reinforcement—and low-friction polymer composites for silent operation. The next frontier is predictive load sensing, where the slide’s resistance subtly adjusts based on weight to provide a perfectly consistent motion feel, whether the drawer holds feathers or frying pans.

In the end, achieving true minimalist elegance is an exercise in obsessive engineering. The goal is not just to hide a component, but to elevate it to such a level of refined performance that its existence is forgotten, leaving only the pure, effortless function it provides. That is the promise—and the profound challenge—of mastering custom concealed drawer slides.