For over two decades, I’ve watched the commercial furniture industry chase the holy grail of modularity. The promise is alluring: endless configurations, rapid reconfiguration, and cost-effective scalability. Yet, too often, the reality falls short at the point of highest user interaction—the drawer. A drawer that sticks, sags, or fails to align isn’t just an annoyance; it’s a failure of the entire modular promise. The core challenge isn’t building a drawer; it’s engineering a custom metal drawer system that performs like a bespoke unit while behaving like a mass-produced, interchangeable component. This is the precision paradox.

The Hidden Challenge: It’s Not the Drawer, It’s the Ecosystem

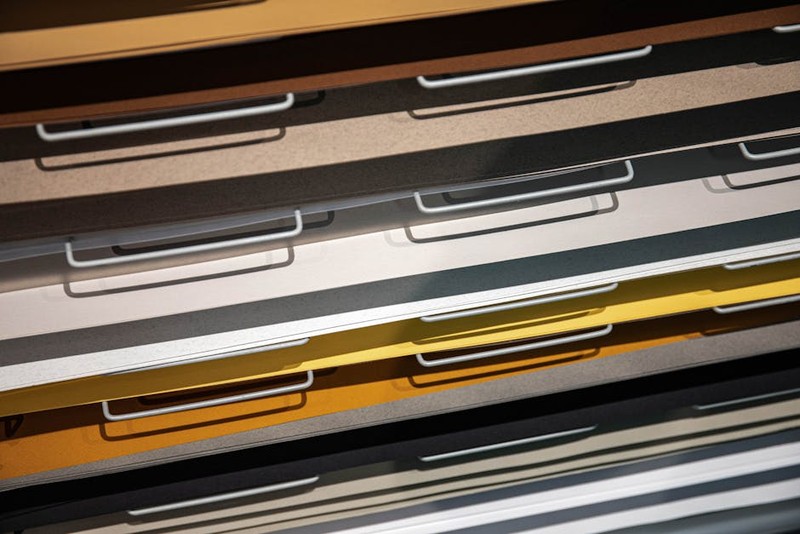

When clients request “modular furniture with custom storage,” they’re envisioning a seamless blend of tailored utility and plug-and-play simplicity. The immediate thought goes to drawer sizes or finishes. But the real complexity lies upstream, in the unseen interface between the custom metal drawer system and the modular carcass.

In a project I led for a flagship tech company’s innovation lab, the initial specification called for 14 different drawer depths across three modular cabinet sizes, all requiring full-extension, soft-close mechanisms. The first prototypes were a disaster. While each drawer box, crafted from 16-gauge powder-coated steel, was flawless in isolation, the cumulative tolerance stack-up when installed in the modular panels was catastrophic. We faced:

Horizontal Misalignment: Drawer fronts were off by up to 3mm, creating a jagged, unprofessional appearance.

Binding Slides: The 100lb-rated slides, perfect on paper, jammed under minor torsional stress from the cabinet frame.

Inconsistent Gaps: Reveals varied from 1.5mm to 4mm, violating the client’s strict aesthetic standards.

The lesson was brutal: You cannot specify a drawer system in a vacuum. Its performance is dictated by the tolerance protocol of the furniture frame it mounts to.

A Case Study in Optimization: The “Tolerance Budget”

The breakthrough came from applying aerospace-inspired “tolerance budgeting” to our custom metal drawer systems. We stopped viewing the drawer as a standalone item and started designing the interface as the primary product.

For the tech lab project, we established a strict, quantified tolerance budget for the entire mounting ecosystem:

| Component | Critical Dimension | Tolerance (±) | Contributor to Final Gap |

| :— | :— | :— | :— |

| Modular Cabinet (Panel) | Slide Mounting Hole Pattern | 0.5 mm | Primary |

| Slide Mechanism (Rail) | Hole Spacing / Squareness | 0.2 mm | Secondary |

| Custom Metal Drawer Box | Mounting Bracket Weld Points | 0.3 mm | Tertiary |

| Drawer Front (Acrylic) | Machining & Mounting | 0.4 mm | Visual Critical |

| Cumulative Potential Variance | | 1.4 mm | Problematic |

| Our Engineered Solution | Integrated Mounting Bracket | 0.7 mm | Controlled |

Our solution was a proprietary, welded-on mounting bracket for the custom metal drawer system. This bracket absorbed and compensated for variances in the cabinet panel. It featured vertical slotted holes, allowing for final micro-adjustment during installation, and was precisely jig-welded to the drawer box to ensure a perfect 90-degree relationship with the slide.

The result? On-site installation time per drawer bank dropped by 40%, and field-fit issues were eliminated. The client’s facilities team could now reconfigure labs over a weekend without needing a master craftsman on hand.

Expert Strategies for Success: Beyond the Spec Sheet

Based on this and similar projects, here is my actionable advice for specifying or designing successful custom metal drawer systems for modular applications.

⚙️ Process: The Three-Point Validation Protocol

Never approve a drawer system based on a single sample. Implement this three-stage validation:

1. Unit Validation: Test a single, complete drawer assembly (box, slide, front) for load capacity, cycle life (aim for 50,000+ cycles), and smooth operation.

2. Cluster Validation: Install a bank of 3-5 drawers in a single modular cabinet unit. This tests for inter-drawer alignment, thermal/electrical ganging (if applicable), and the true load on shared cabinet dividers.

3. Field-Mock Validation: Install the cluster into a mock-up of the actual modular panel system, complete with leveling legs, wall attachments, and adjacent modules. This exposes tolerance stack-up in real-world conditions.

💡 Material & Mechanism Insights

Gauge is a Guide, Not a Gospel: 18-gauge steel is standard, but for drawers wider than 24″, consider 16-gauge to prevent “oil-canning” (flexing of the broad front panel). The cost increase is marginal, the performance gain is massive.

The Slide is the Heart: Do not default to the cheapest 75lb slide. Specify a slide with a true 100lb+ dynamic load rating, a steel ball bearing race (not nylon), and a built-in side-to-side adjustment feature. Brands like Accuride or Grass offer models designed for tolerance forgiveness.

Finish for Function: A powder-coated interior is durable, but for labs or environments with liquids, specify a stainless steel drawer box or a coated finish with a fully welded and ground interior seam to prevent fluid ingress and corrosion.

The Future: Integrated Intelligence

The next frontier for custom metal drawer systems is embedded IoT. In a current R&D project, we’re prototyping drawers with RFID-tagged fronts and capacitive sensors in the slides. This allows inventory management systems to track which drawer is opened, when, and for how long—adding a layer of data intelligence to physical modularity. The challenge, again, is power and data integration within the modular frame, a puzzle we’re solving with low-energy Bluetooth and inductive charging pads built into the cabinet backwalls.

The ultimate takeaway is this: The success of modular commercial furniture is won or lost at the millimeter level. By treating the custom metal drawer system not as an accessory but as the critical, engineered interface between human need and modular form, you unlock true flexibility, durability, and user satisfaction. Specify the interface, and the drawer will follow.