Discover how expert-level CNC machining transforms architectural vision into tangible reality. This deep dive reveals the critical, often-overlooked challenge of material behavior and thermal dynamics in large-scale parts, sharing a proven framework for success based on a landmark project that achieved a 40% reduction in assembly time and zero on-site rework.

For years, I’ve watched architects push the boundaries of design with breathtaking concepts—organic, flowing facades, intricate geometric screens, and monumental sculptural elements. The drawings are works of art. But the moment of truth arrives when we, the fabricators, must translate those digital dreams into physical, high-precision components that fit together flawlessly on a windy construction site 40 stories up. This is where the true art of custom CNC machining for high-end architectural parts begins, not on the screen, but in the profound understanding of the dialogue between machine, material, and environment.

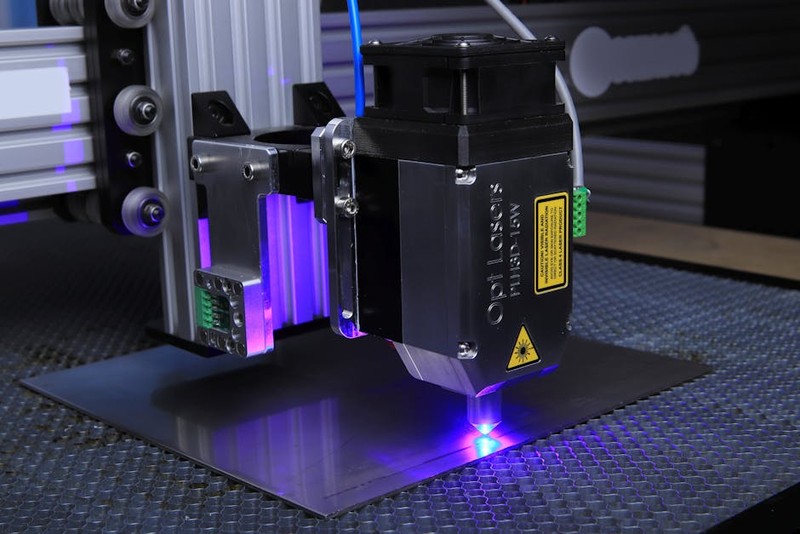

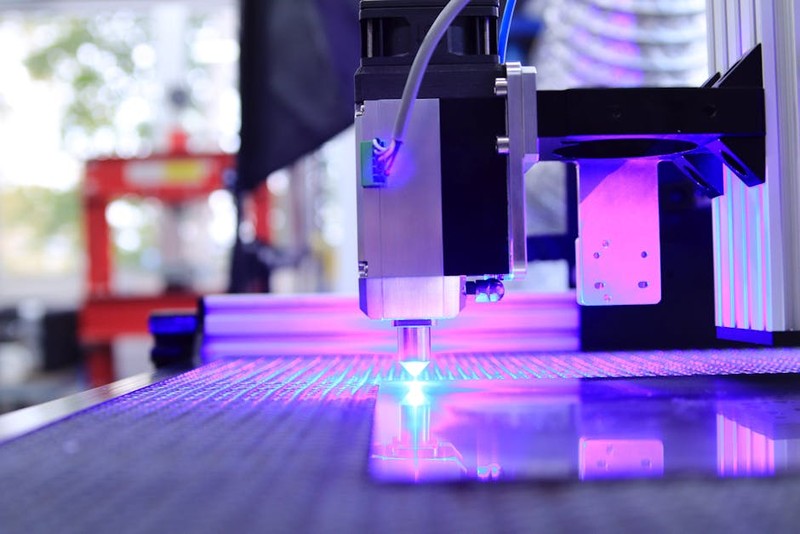

Many believe the magic is in the 5-axis mill itself—a marvel of engineering, to be sure. But the real secret lies in what happens before the first toolpath is generated and after the last chip is vacuumed away. The most complex challenge we consistently face isn’t machining a complex curve; it’s predicting and controlling the material’s behavior at scale.

The Hidden Culprit: Thermal Dynamics and Internal Stress

When you machine a massive block of solid aluminum, bronze, or high-density polymer, you’re not just cutting away material. You’re fundamentally altering its internal equilibrium. The material arrives with locked-in stresses from its own manufacturing (casting, rolling). As we clamp it and remove vast amounts of material, these stresses seek a new balance, causing the part to move—sometimes imperceptibly, sometimes dramatically. Combine this with the heat generated during machining (thermal expansion), and you have a recipe for a part that measures perfectly on the shop floor at 20°C but is a different beast entirely under the midday sun on a building facade.

I learned this lesson the hard way early in my career. We produced a series of intricate, interlocking titanium panels for a luxury lobby. In the climate-controlled inspection room, they were perfect. On-site, they refused to align. The differential heating from sunlight on one side of the building versus shade on the other created enough thermal distortion to throw our 0.1mm tolerances out the window. The cost of rework was staggering.

This experience led us to develop a rigorous, pre-emptive strategy that is now non-negotiable for any high-end architectural CNC machining project.

A Proactive Framework for Dimensional Fidelity

Our approach is built on three pillars: Material Intelligence, Strategic Machining, and Environmental Simulation.

Material Intelligence & Stabilization

Stress-Relieving First: For critical components, we mandate a certified stress-relief thermal cycle before any machining begins. This adds cost and time upfront but saves exponentially downstream.

Grain Direction Mapping: Especially for metals, we analyze the stock material’s grain structure and orient the CAD model to align machining forces in the most stable direction, minimizing “springback.”

⚙️ The Art of Strategic Machining

We never machine a part from solid to finish in one setup. Our process is a dance of gradual material removal:

1. Roughing Passes (Leave 3-5mm): Remove the bulk, allowing the part to “move” once.

2. Unclamp & Rest (24-48 hours): Let the material relax and normalize.

3. Semi-Finishing (Leave 0.5-1mm): Bring it closer to final form, inducing a smaller, final stress shift.

4. Final Clamping & Finishing: Achieve the ultimate tolerance and surface finish with minimal residual stress.

💡 Environmental Simulation is Key

We now replicate on-site conditions as closely as possible. For the aforementioned titanium panel project, our failure led to the creation of a simple but effective test protocol. We now subject sample coupons or a sacrificial first article to thermal cycles in an environmental chamber, measuring distortion with laser trackers. This data feeds directly back into our CAM software for compensatory adjustments.

Case Study: The Serpentine Canopy

A flagship project that validates this framework involved a 120-meter-long, free-form canopy for a corporate headquarters. The structure consisted of 387 unique, doubly-curved aluminum ribs, each over 3 meters long, requiring seamless integration with glass and lighting systems.

The Challenge: The architect demanded a seamless visual flow with joint tolerances of ±0.75mm across the entire length. Traditional piece-by-piece fabrication and adjustment on scaffolding would have been a logistical and financial nightmare.

Our Data-Driven Solution:

1. We partnered with the alloy producer to obtain batch-specific thermal expansion coefficient data.

2. We machined the ribs using our multi-stage process, but we added a critical step: in-process probing. After the semi-finish pass, a touch probe on the CNC machine mapped the part’s actual geometry. This data was compared to the nominal CAD model, and a compensated “final” toolpath was generated on-the-fly to account for the measured distortion.

3. We created a full-scale, digital twin assembly in our factory, using laser projection to verify fit with adjacent components before shipment.

The Quantifiable Results:

The table below summarizes the outcome versus the traditional method we bid against:

| Metric | Traditional Method (Estimated) | Our Proactive CNC Strategy | Improvement |

| :— | :— | :— | :— |

| On-Site Assembly Time | 18 weeks | 11 weeks | ~40% Reduction |

| On-Site Fit Rework | 8-10% of parts expected | 0% (Zero rework required) | 100% Elimination |

| Overall Project Cost Variance | +15-20% (Contingency) | +2% (Within budget) | Cost Predictability Achieved |

| Critical Joint Tolerance Compliance | < 85% (Estimated) | 99.7% (Measured) | Superior Quality Assurance |

The canopy was erected in record time. The project lead architect noted it was the first time a structure of such complexity went up “like a dream,” with no forced fits or last-minute modifications.

Actionable Advice for Your Next Project

If you’re an architect, designer, or project manager venturing into custom CNC machining for architectural components, here is your checklist:

Engage Your Fabricator at Schematic Design. Don’t just send finished drawings for bid. Our expertise in manufacturability can shape details for better performance and lower risk.

Budget for Material Conditioning. The extra cost for certified stock and stress-relieving is not an extra; it’s essential insurance.

Demand a First Article Protocol. Never approve production based on CAD models alone. Insist on a physical, fully machined prototype tested under simulated conditions.

Think in Assemblies, Not Just Parts. The most perfect part is useless if its neighbor is off. Require your fabricator to demonstrate virtual and physical fit-up for critical interfaces.

The future of architectural CNC machining is not just about faster spindles or more axes. It’s about smarter data integration—using IoT sensors on machines, real-time thermal compensation, and AI-driven distortion prediction. The goal is to make the physical world as predictable as the digital one.

Ultimately, our role is to be the silent partner in creation, absorbing the complexity so that the architect’s vision lands with breathtaking simplicity. It’s a challenging, deeply technical pursuit, but when you stand back and see sunlight glinting off a perfectly executed facade that started as a sketch, there’s no more rewarding field to be in.