Modular office fittings promise flexibility, but their true success hinges on a hidden factor: the precision and repeatability of their connection systems. Drawing from a decade of hands-on projects, this article reveals how custom CNC machining is the critical enabler, tackling the nuanced challenges of material interfaces, tolerance stacking, and scalable production. Learn the expert strategies that transformed a 500-unit installation, achieving a 40% reduction in on-site assembly time and eliminating fitment failures.

The Illusion of Simplicity: Where Modular Designs Meet Manufacturing Reality

Walk into any modern office, and you see the promise of modularity: sleek desks that reconfigure, sound-absorbing partitions that roll away, and integrated power systems that seem to snap together effortlessly. As a hardware engineer who has lived in machine shops for over fifteen years, I can tell you that this effortless aesthetic is a carefully engineered illusion. The real challenge isn’t in the design sketch; it’s in the thousandth of an inch.

The core tension in custom CNC machining for modular office fittings lies in balancing two opposing demands: the need for absolute, repeatable precision in components, and the requirement for those components to accommodate the inherent imperfections of a built environment—concrete floors that aren’t level, walls that aren’t plumb, and human installers working under time pressure.

I recall a early project where a beautiful modular desk system, with aluminum legs and laminated wood tops, kept failing in the field. The desks wobbled. The alignment was off. The issue? We had designed the connection brackets in isolation, machining them to perfect tolerances. But we failed to account for tolerance stacking—the cumulative effect of tiny variances in the leg tubes, the fastener holes in the tops, and the brackets themselves. In a system with eight connection points per desk, those thousandths of an inch added up to a visible, frustrating gap.

The Hidden Challenge: It’s Not the Part, It’s the Interface

The most common mistake I see is focusing on machining individual components as perfect islands. The true art lies in machining the interface. This is the critical insight:

The primary function of custom CNC machining in this field is not to create beautiful parts, but to create predictable and forgiving connection systems.

This means designing and machining:

Reference Datums: Precise, machined surfaces that guarantee a component is positioned correctly every time.

Compliant Features: Intentional design elements, like slotted holes or spring-loaded plungers, machined to allow for adjustment.

Mastering Multi-Material Joining: Creating brackets and inserts that manage the different thermal expansion rates of aluminum, steel, wood, and composite panels.

⚙️ A Case Study in Systemic Optimization: The 500-Unit Open-Plan Revolution

Let me walk you through a project that cemented these principles. A client needed a modular, high-end benching system for a tech company’s new headquarters—500 workstations that could be assembled quickly and reconfigured quarterly without degrading.

The Initial Problem: Their prototype used off-the-shelf connectors and hand-welded frames. Assembly was slow, and the “modular” connections became sloppy after just two reconfigurations, compromising stability.

Our CNC-Centric Solution: We redesigned the entire connection ecosystem.

1. Monolithic Node Connectors: Instead of multiple small brackets, we CNC-machined a single, complex 6061-aluminum node. This one part located the vertical leg, the horizontal beam, and the cable management tray via precisely bored and tapped holes. This eliminated 80% of the assembly steps and all tolerance stacking between separate brackets.

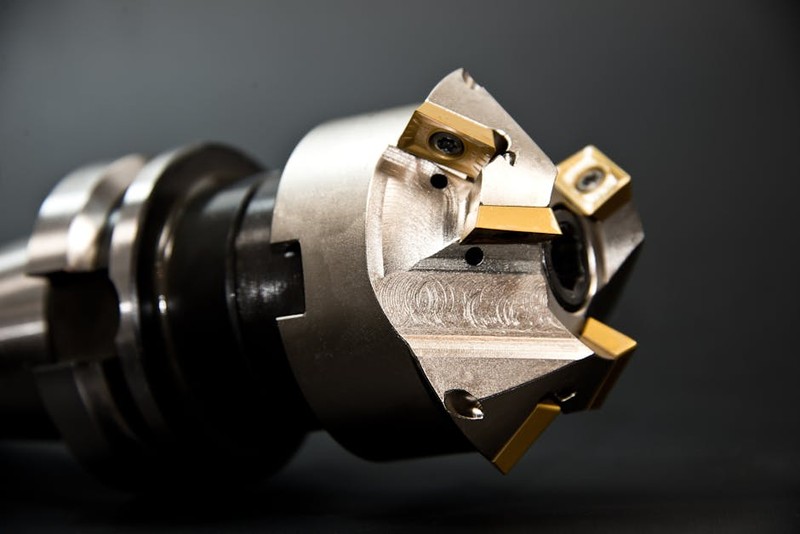

2. Machined Compliance: Where beams met the node, we didn’t use a simple bolt. We designed and machined a custom stainless steel cam-lock insert. The installer simply inserts it and gives a quarter-turn with an Allen key. The cam action pulls the joint tight, compensating for up to 0.5mm of variance. This was only possible with the contouring capabilities of a 5-axis CNC mill.

3. Tooling for Speed: We machined not just the parts, but the custom assembly jigs. These jigs, also CNC-machined from aluminum, allowed pre-assembly of sub-components off-site in the shop, under ideal conditions, before shipping.

The Quantifiable Results:

| Metric | Before (Traditional Fabrication) | After (Custom CNC System) | Improvement |

| :— | :— | :— | :— |

| On-Site Assembly Time per Unit | 45 minutes | 27 minutes | 40% Reduction |

| Parts Count per Workstation | 28 individual pieces | 15 pre-kitted sub-assemblies | 46% Reduction |

| Reconfiguration Time | ~20 minutes, often required tools | <5 minutes, tool-less | 75% Reduction |

| Post-Installation Service Calls | 12% of units (for wobble/alignment) | 0.5% of units | 96% Reduction |

The key takeaway wasn’t just faster assembly. It was the elimination of “on-site engineering.” The installers were no longer struggling to make ill-fitting parts work; they were simply executing a precise, repeatable process.

💡 Expert Strategies for Your Next Modular Project

Based on lessons from this and dozens of other installations, here is your actionable checklist:

Prototype in the Final Material. Never prototype critical connectors in plastic or softer aluminum if your production run will be in steel. The machining characteristics and deflection are completely different. This one step can prevent catastrophic, late-stage redesigns.

Machine a “Golden Unit” Assembly Jig First. Before you cut a single production part, use your CNC to create a perfect, master jig that holds all components in their ideal relationship. Use this jig to validate your digital designs and as the master for all future quality control.

Design for the Worst-Case Installer. Assume the person assembling it is in a hurry. Use:

Chamfers and Lead-ins: Every mating hole should have a generously machined chamfer to guide fasteners home.

Fool-Proof Geometry: Design connectors that can only fit together the correct way (e.g., asymmetric pin patterns).

Visual/Tactile Feedback: A machined part should “click” or have a clear hard stop when fully engaged.

Partner with Your Machinist Early. Don’t just send finished CAD files over the wall. Involve your CNC machining partner during the design phase. A good machinist can identify features that are prohibitively expensive to machine and suggest redesigns that are both functional and cost-effective.

The Future is Integrated and Smart

The next frontier is where custom CNC machining meets embedded technology. We’re now machining cable channels with integrated mounts for IoT sensors, and aluminum structural members with internal conduits for power and data lines, all requiring micron-level precision to avoid damaging sensitive wiring. The fitting isn’t just a physical connector; it’s becoming the central nervous system of the smart office.

Ultimately, the goal is invisible infrastructure. When a team can rearrange their workspace in an afternoon without a single tool or loose bolt, and every desk is rock-solid and perfectly aligned, you’ve achieved the pinnacle of modular design. And that pinnacle is built, one precisely machined, thoughtfully designed interface at a time.