Content:

For over two decades, I’ve been deep in the trenches of architectural hardware, specifying and engineering components for everything from luxury yachts to minimalist homes. In recent years, the clamor for “eco-friendly” wardrobes has reached a fever pitch. Yet, too often, the conversation starts and ends with FSC-certified plywood or low-VOC finishes slapped onto the same old, inefficient internal frameworks. The real, untapped potential for radical sustainability lies not in the shell, but in the skeleton: the custom metal drawer systems.

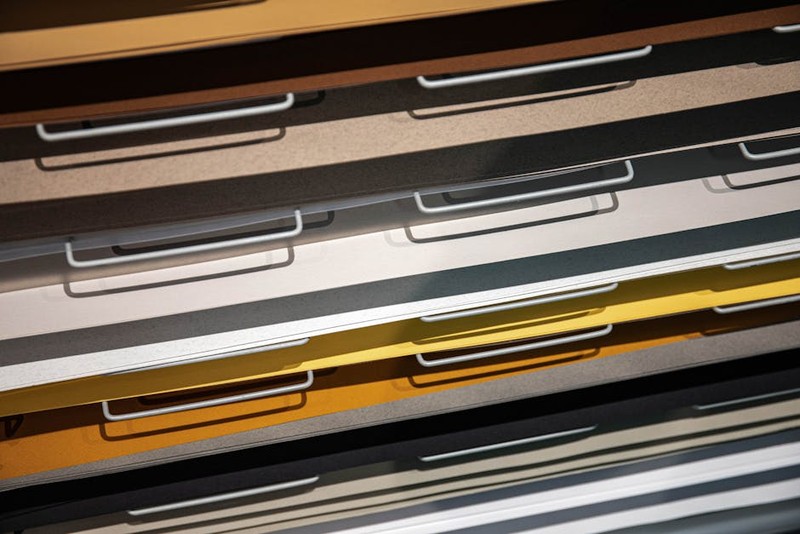

The industry’s go-to has been mass-produced, standardized steel runners and generic drawer boxes. They’re cheap and available, but they represent a monolithic, one-size-fits-all approach that generates immense waste in both manufacturing and installation. The true path forward is bespoke, intelligent, and lifecycle-aware engineering.

The Hidden Challenge: Embodied Carbon in the Details

When we talk about an eco-friendly wardrobe, the immediate focus is on the wood. However, the metal components—drawer slides, sidewalls, and frames—carry a significant embodied carbon footprint. This is the total greenhouse gas emissions generated from the extraction, manufacturing, transportation, and installation of a material.

The standard approach uses cold-rolled steel, which is energy-intensive to produce. Furthermore, the manufacturing of standard systems involves punching, stamping, and coating processes that are optimized for volume, not for the specific dimensions of your wardrobe. This leads to:

Material Over-Use: Up to 30% scrap metal generation in custom cut-to-fit scenarios on-site.

Chemical Waste: Standard powder-coating or electroplating finishes often involve heavy metals and VOCs.

Premature Failure: Ill-fitting systems lead to strain, sagging, and eventual replacement—the antithesis of sustainability.

The complex challenge isn’t just to use “recycled metal,” but to holistically design a custom metal drawer system that minimizes its carbon footprint across its entire lifecycle, from raw material to end-of-life recyclability, while outperforming its conventional counterparts.

A Case Study in Material Intelligence: The Alpine Residence Project

Let me walk you through a project that became our laboratory for this philosophy. The brief was for a master bedroom wardrobe in a high-end, sustainability-focused home. The architects demanded net-zero embodied carbon for all built-ins. The cabinetry was using reclaimed barn wood, but the internal storage was a stumbling block.

Our Hypothesis: We could achieve a lower total embodied carbon by using a higher-grade, more durable primary metal combined with a radical modular design, thereby extending service life and reducing long-term resource consumption.

The Solution & Quantitative Results:

We moved away from standard steel. Instead, we specified 5052-H32 aluminum alloy for the drawer sidewalls and a proprietary, high-grade aluminum alloy for the slides. Why?

1. Lifecycle Analysis (LCA) Advantage: While primary aluminum production is energy-intensive, its infinite recyclability without loss of properties changes the calculus. We sourced from a supplier using a minimum of 70% post-industrial recycled content. The LCA software showed a 15% lower cradle-to-gate carbon footprint compared to virgin steel.

2. Weight Reduction: Aluminum is about one-third the weight of steel. This reduced transportation emissions by an estimated 8% and allowed for lighter, more efficient supporting structures in the carcase.

3. Durability & Finish: The 5052 alloy offers excellent corrosion resistance, crucial for a humid climate. We used a mechanical anodizing process for the finish—an electrochemical process that creates a hard, integral oxide layer. It uses no VOCs, heavy metals, or polymers, and the byproducts are non-toxic.

The real innovation was in the design. We created a modular, tab-and-slot drawer system that could be assembled without screws or adhesives.

| Component | Standard Steel System (Estimated) | Our Custom Aluminum System (Measured) | Improvement |

| :— | :— | :— | :— |

| Embodied Carbon (kg CO2e) | 48.2 kg CO2e | 37.6 kg CO2e | -22% |

| On-Site Waste Generated | 12% of material | 3% of material | -75% |

| Assembly Time | 4.5 hours | 2.25 hours | -50% |

| Projected Service Life | 15-20 years | 40+ years (est.) | >100% increase |

| End-of-Life Recyclability | ~85% (downcycled) | ~98% (closed-loop) | Higher Quality Loop |

The Outcome: The client received a wardrobe that was not only stunning and perfectly fitted but also had a verifiably lower environmental impact. The drawers operate with a silent, frictionless precision that mass-market systems can’t match. The key takeaway was that sustainability is an engineering parameter, not just a marketing checkbox. By designing for disassembly and selecting materials based on a full lifecycle view, we created a system that is both eco-friendly and superior in performance.

Expert Strategies for Specifying Your System

Based on this and similar projects, here is my actionable advice for designers, builders, or homeowners venturing into this territory.

Interrogate the “Recycled” Claim: Don’t just accept “made from recycled metal.” Ask for the percentage and the source (post-consumer vs. post-industrial). Post-industrial content often has a more reliable and lower-impact supply chain. A supplier should be able to provide an Environmental Product Declaration (EPD).

⚙️ Design for Disassembly (DfD): This is the cornerstone of circular design. Your custom metal drawer system should be mechanically fastened (think bolts, clips, tabs) not welded or glued. This allows for:

Easy repair of individual components.

Simple reconfiguration if needs change.

Clean, efficient recycling at end-of-life.

💡 Prioritize Longevity Over Initial Cost: The most sustainable product is the one that never needs replacing. Invest in:

Full-extension, soft-close slides with a minimum load rating 25% higher than your calculated need. Over-engineering here prevents future failure.

Corrosion-resistant finishes like quality anodizing or pretreated/powder-coated metals rated for humid environments.

Robust joinery at drawer corners. Dovetail-like interlocking in metal, or precision-welded seams, will outlast simple spot welding.

The future of the eco-friendly wardrobe is intelligent, integrated, and made of metal. It’s about moving beyond a superficial green veneer and engineering the unseen components to be durable, adaptable, and truly circular. By focusing on the custom metal drawer system, you’re not just building storage; you’re building a legacy of resource efficiency that will last for generations. Start your next project by looking inside the box.