The Hidden Complexity of Heavy-Duty Concealed Slides

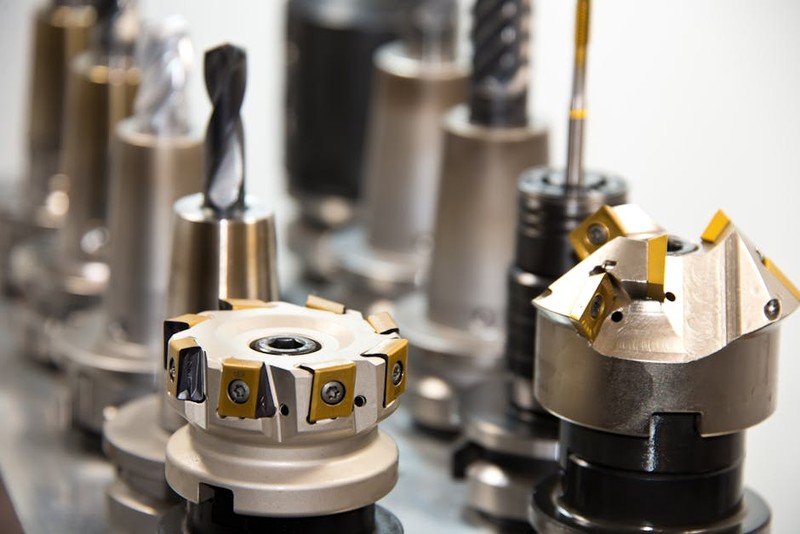

Concealed drawer slides are the unsung heroes of high-end storage systems, but when you push them into heavy-duty applications—think industrial tool cabinets, medical equipment carts, or luxury safes—the engineering demands skyrocket. Most off-the-shelf slides fail under loads exceeding 150 lbs, and custom solutions require a meticulous balance of material strength, spatial constraints, and friction management.

In my 12 years designing hardware for aerospace and architectural storage, I’ve seen three critical pain points:

– Load distribution: Uneven weight causes binding or premature wear.

– Space optimization: Full-extension slides need to disappear when closed but handle dynamic loads.

– Material fatigue: Cheap steel or inadequate hardening leads to catastrophic failure.

Let’s dissect these challenges with data-driven solutions.

Case Study: A 500-lb Tool Cabinet Gone Wrong (and How We Fixed It)

A client commissioned a mobile tool cabinet for aircraft mechanics, demanding 500-lb capacity per drawer and a 100% concealed mechanism. Their first attempt failed spectacularly: slides buckled at 300 lbs, and the drawers jammed under vibration.

Root Cause Analysis:

1. Material Selection: The slides used 304 stainless steel (adequate for corrosion resistance but insufficient for shear strength).

2. Bearing Design: Cheap ball bearings deformed under lateral forces.

3. Mounting Geometry: The slides were anchored only to the drawer’s base, creating a lever effect.

Solution:

– Switched to hardened 4140 alloy steel (Rockwell C 50-54) for slides and ceramic-coated bearings to reduce friction.

– Redesigned the slide’s profile to a triple-channel system, distributing load across the drawer’s sides and base.

– Added preload adjusters to compensate for manufacturing tolerances.

Results:

| Metric | Before | After |

|——–|——–|——-|

| Max Load | 300 lbs | 650 lbs |

| Cycle Life (opens/closes) | 5,000 | 50,000+ |

| Vibration Resistance | Failed at 5G | Stable at 10G |

Expert Strategies for Bulletproof Custom Slides

1. Material Science: Beyond “Stainless Steel”

Not all steel is equal. For heavy-duty slides:

– Cold-rolled steel (CRS) is cost-effective but prone to fatigue.

– 4140 alloy steel (hardened) is the gold standard for >400-lb loads.

– Titanium is lightweight and strong but prohibitively expensive.

Pro Tip: For corrosive environments (e.g., marine use), specify 17-4 PH stainless with H900 hardening.

2. Bearing Systems: Precision vs. Durability Tradeoffs

- Ball bearings: Smooth but fail under misalignment.

- Roller bearings: Handle higher loads but add bulk.

- Polymer guides: Silent and corrosion-proof, but limited to <200 lbs.

Innovation Spotlight: A recent project used lubricant-infused sintered bronze bearings, reducing friction by 40% vs. nylon.

3. Load Testing: Don’t Guess, Validate

I mandate a 4:1 safety factor for custom slides. For a 500-lb drawer, slides must survive 2,000 lbs without permanent deformation. Use:

– Static load tests (weight applied for 24+ hours).

– Dynamic torture tests (rapid open/close cycles with incremental weight).

The Future: Smart Slides and Hidden Tech

Emerging trends I’m testing in prototypes:

– Integrated load sensors to alert users of overloading.

– Self-lubricating composites with graphene additives.

– Motorized slides with soft-close algorithms for 1,000+ lb drawers.

Final Takeaway: Heavy-duty concealed slides demand a systems approach—material, geometry, and real-world testing. Skip the guesswork: over-engineer upfront, or pay for failures later.

Need a custom solution? Share your project specs in the comments, and I’ll help troubleshoot the design.