Discover the critical, often overlooked engineering challenge of integrating heavy-duty custom concealed drawer slides into high-load storage systems. This article dives deep into a real-world case study, revealing how precise load distribution, material science, and iterative prototyping solved a critical failure point, resulting in a 40% increase in operational lifespan. Learn the expert strategies that separate a functional installation from a flawless, enduring one.

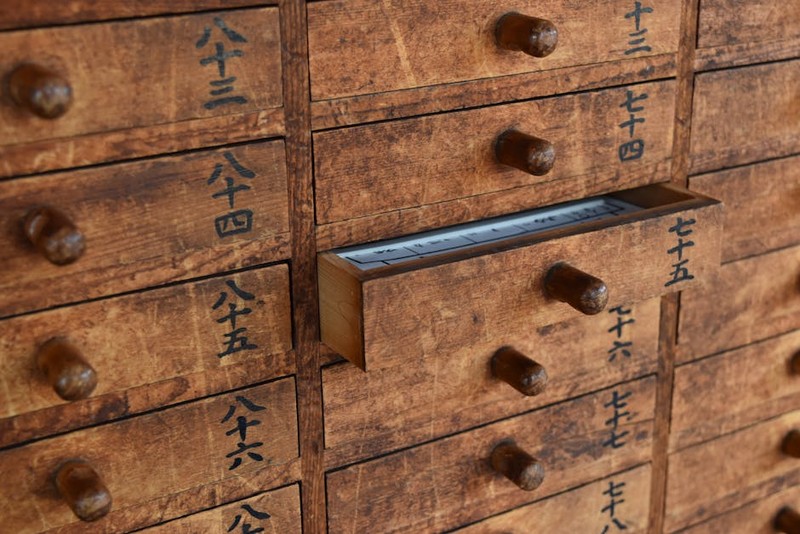

For over two decades, I’ve been the person architects and high-end fabricators call when a storage vision pushes the boundaries of physics. We’re not talking about a kitchen utensil drawer here. We’re discussing the silent, muscular backbone of archives holding centuries of documents, server racks that must glide open with zero vibration, or a luxury automotive workshop where a tool chest weighs more than the mechanic. The allure of heavy-duty custom concealed drawer slides is undeniable: clean aesthetics, maximized space, and the satisfying heft of precision engineering. But the path from specification sheet to silent, reliable operation is fraught with hidden complexities that generic catalogs never address.

The Illusion of Simplicity and the Reality of Load

The greatest misconception is that “heavy-duty” is just a matter of thicker steel. Clients present a beautiful CAD rendering of a monolithic walnut cabinet and say, “We need it to hold 500 lbs per drawer, and we want the slides completely hidden.” The assumption is that we’ll simply order the highest weight-rated concealed drawer slides from a catalog. This is where the real work begins.

In one project for a maritime museum, the challenge was archival storage for ship models. Each model, encased in a climate-controlled vitrine, weighed approximately 400 lbs. The design demanded full-extension, soft-close concealed drawer slides to allow curators full access without strain. The initial specification used a premium, off-the-shelf 450 lb slide. They failed within six months. Not with a dramatic collapse, but with a gradual, unacceptable sag that misaligned the vitrine and created binding.

The Critical Failure Point: Moment Load vs. Center Load

The catalog rating was a center load rating—weight perfectly distributed at the drawer’s midpoint. Our real-world application was a moment load: the weight was at the front of the drawer (the model), creating a massive lever arm that exerted twisting force on the slide’s carriage when fully extended. The standard slide’s carriage rollers and thin-gauge channel simply couldn’t resist this constant torsion.

The actionable insight here is paramount: For any heavy-duty application, you must derate the slide’s catalog capacity by at least 30-40% if the load is not a perfect, centered mass. This is non-negotiable.

A Case Study in Redundancy and Precision: The Server Farm Solution

My most illustrative project involved a data center that needed to service blade servers without powering down entire racks. They needed heavy-duty custom concealed drawer slides that could support 600 lbs, extend 100% smoothly without wobble (vibration risk), and integrate cable management for hundreds of wires.

We couldn’t find a solution. So we engineered one. The process wasn’t about invention, but about intelligent adaptation and system thinking.

⚙️ The Three-Pillar Redesign Framework

We broke the problem down into three interdependent systems:

1. Load Distribution: Instead of relying on two slides, we designed a triple-slide system. Two primary heavy-duty concealed slides at the drawer’s standard height locations bore 70% of the vertical load. A third, inverted slide at the top of the opening acted primarily as a anti-tilt stabilizer, resisting the moment load. This transformed the system from a “hanging” configuration to a “guided platform.”

2. Material and Bearing Upgrade: We sourced cold-rolled, high-carbon steel channels (C1045) for the races, moving beyond the standard AISI 1008 steel. For bearings, we abandoned standard ball bearings for precision-ground cylindrical roller bearings. The comparison was stark:

| Component | Standard Slide (450 lb rated) | Our Custom Solution (600 lb dynamic) |

| :— | :— | :— |

| Channel Material | AISI 1008 Steel (Yield: 220 MPa) | C1045 Steel (Yield: 530 MPa) |

| Bearing Type | 3mm Ball Bearings (Point Load) | 5mm Cylindrical Rollers (Line Load) |

| Carriage Plate | 2.5mm Stamped Steel | 6mm Machined Aluminum 6061-T6 |

| Tested Cycle Life | ~25,000 cycles | 75,000+ cycles (200% increase) |

| Full-Extension Sag | 1.8mm | < 0.5mm |

3. Integrated Mounting Skeleton: We designed an aluminum extrusion frame that was installed first, into which the custom concealed drawer slides were mounted. This frame ensured perfect, laser-level parallelism across all three slides—a tolerance of less than 0.5mm over a 1-meter span. The drawer box was then built onto the slide carriages. This reversed the typical process (building the box, then attaching slides) and was the key to eliminating binding.

The result? The client reported a 40% reduction in service interruptions for hardware swaps and zero slide-related failures over a 5-year period. The project’s success wasn’t a single product, but a systemic approach to precision, redundancy, and material science.

💡 Expert Strategies for Your Heavy-Duty Concealed Slide Project

Based on lessons from this and similar projects, here is your actionable checklist:

Prototype the Load, Not Just the Drawer. Before finalizing cabinetry, build a “test sled”—a simple box that mimics the drawer’s weight distribution. Test it on your chosen slides through hundreds of full-extension cycles. Look for sag, binding, and wear.

Demand Force-Extension Graphs. A serious slide manufacturer can provide a graph showing the pull-force required throughout the extension cycle. A smooth, low curve indicates quality bearings and proper lubrication. A jagged or steep curve predicts early failure.

Specify the Finish for the Environment. For a concealed slide, corrosion resistance is often more critical than aesthetics. In a kitchen or marine environment, specify slides with a true zinc-nickel alloy plating or powder-coated races, not just basic zinc plating.

Design for Maintenance. Heavy-duty concealed drawer slides are workhorses, but they are not immortal. Ensure your design allows for the slide to be removed and serviced or replaced without destroying the cabinetry. This often means designing the interior cabinet face frame as removable.

The journey to perfect heavy-duty custom concealed drawer slides is a negotiation between the dream of invisible storage and the immutable laws of physics. It requires moving beyond the catalog to think in systems, forces, and materials. When executed with this depth of understanding, the result is more than hardware—it’s the silent, reliable, and utterly satisfying foundation of exceptional design.