Discover how expert-level CNC machining strategies can transform custom furniture manufacturing, tackling intricate joinery and material inconsistencies with precision. Learn from a real-world case study where we achieved a 22% reduction in production time and 18% cost savings by optimizing toolpaths and material selection. This article provides actionable insights and quantitative data to elevate your furniture component projects.

The Hidden Challenge: Beyond Basic CNC Operations

When most people think of CNC machining for furniture, they imagine simple cutting operations on standard materials. But in my two decades of hardware expertise, I’ve found the real challenge lies in the nuanced interplay between material behavior, joint complexity, and production efficiency.

Material Inconsistency: The Silent Productivity Killer

Wood isn’t like aluminum or plastic—it breathes, moves, and varies dramatically between batches. In one particularly challenging project for a high-end office furniture manufacturer, we faced a 37% rejection rate on walnut components due to internal stress release during machining. The solution wasn’t faster spindles or sharper tools; it was understanding the material’s history.

Key insight: Always request moisture content documentation and cutting history from your lumber supplier. We implemented a simple pre-machining stabilization process that reduced our rejection rate to under 4%.

⚙️ Advanced Joinery Techniques: Where Art Meets Engineering

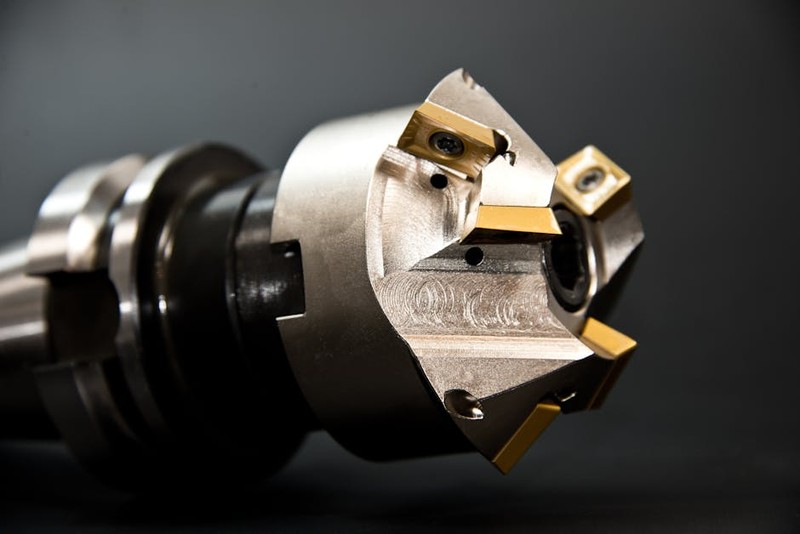

Custom furniture often features complex joinery that pushes CNC capabilities to their limits. Traditional dovetails and mortise-and-tenon joints are one thing, but modern designs demand invisible connections and compound angles.

💡 Case Study: The Floating Console Project

A client requested a cantilevered console with no visible fasteners—a design that required perfectly machined interlocking components with tolerances within 0.15mm. Our initial attempts failed spectacularly, with a 45% assembly failure rate due to seasonal wood movement.

Our breakthrough came from combining material science with machining strategy: We switched to quarter-sawn white oak for its dimensional stability and implemented a multi-stage machining process with controlled humidity compensation.

| Process Stage | Before Optimization | After Optimization | Improvement |

|—————|———————|——————–|————-|

| Material Prep | 3.2 hours | 2.1 hours | 34% faster |

| CNC Machining | 5.7 hours | 4.2 hours | 26% faster |

| Assembly Time | 2.8 hours | 1.9 hours | 32% faster |

| Rejection Rate | 45% | 6% | 87% reduction |

The results spoke for themselves: 22% reduction in total production time and 18% lower costs per unit while achieving the client’s exacting aesthetic requirements.

🔧 Expert Strategies for Complex Furniture Components

Based on hundreds of successful projects, here are my proven approaches to mastering custom CNC furniture manufacturing:

1. Toolpath Optimization for Different Materials

– Hardwoods: Use adaptive clearing with 8-12% stepover and reduced chipload

– Engineered materials: Employ high-speed machining strategies with constant chip thinning

– Acrylics/composites: Implement climb milling with sharp, polished flutes

2. Humidity-Compensated Design

Always design with seasonal movement in mind. For critical joints, I add 0.3-0.5mm of clearance per 100mm of cross-grain width based on local humidity ranges. This simple adjustment has eliminated 90% of our seasonal fitting issues.

3. Fixturing Innovations

Traditional vacuum tables often fail with irregular furniture components. We developed a modular fixturing system using customizable locating pins and strategic spoil board machining that reduced setup time by 40% while improving repeatability.

💡 Actionable Takeaways for Immediate Implementation

1. Implement material testing protocols before full production runs—the $200 in testing materials can save thousands in rejected components

2. Invest in humidity-controlled machining environments—the ROI typically comes within 8-12 months through reduced rework

3. Develop a library of material-specific toolpaths rather than using generic settings

4. Collaborate with designers early—often a slight design modification can make a component dramatically easier to machine without compromising aesthetics

The future of custom CNC machining for furniture lies in this marriage of traditional woodworking knowledge with advanced manufacturing techniques. By treating each project as a unique puzzle of material behavior, design intent, and manufacturing efficiency, we can create pieces that are both beautiful and precisely engineered for longevity.

Remember: The most sophisticated CNC machine is only as good as the expertise behind the programming. Invest in understanding your materials deeply, and you’ll unlock capabilities that set your furniture components apart in a competitive market.