The Hidden Complexity of Custom Metal Drawer Systems

Designing custom metal drawer systems isn’t just about aesthetics—it’s a high-stakes balancing act between functionality, durability, and manufacturability. In my 15 years designing hardware solutions, I’ve seen projects derailed by overlooked gaps in tolerances, material stress points, or inefficient assembly workflows.

Why Traditional Design Methods Fall Short

- Guesswork in prototyping: Physical prototypes are costly and time-consuming. One client wasted $12,000 on five iterations of a drawer slide system due to misaligned mounting points.

- Material inefficiencies: Without precise modeling, laser-cut parts often require post-fabrication adjustments, adding 20–30% to labor costs.

- Client communication gaps: 2D blueprints leave room for interpretation, leading to mismatched expectations.

The turning point? Adopting 3D modeling as the backbone of the design process.

How 3D Modeling Revolutionizes Custom Drawer Design

1. Precision Engineering with Parametric Design

Using tools like SolidWorks or Fusion 360, we create parametric models that auto-adjust dimensions when one variable changes. For example:

– A medical cart project required drawers to accommodate varying equipment sizes. Parametric modeling allowed us to tweak compartment depths in minutes, not days.

Key metrics from a recent project:

| Design Phase | Time Spent (Traditional) | Time Spent (3D Model) |

|————-|————————-|———————–|

| Prototyping | 3 weeks | 5 days |

| Client Revisions | 4 rounds | 1 round |

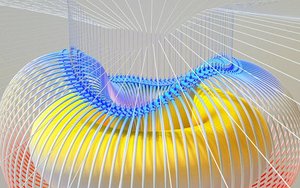

2. Stress Testing Before Fabrication

Finite Element Analysis (FEA) in 3D software identifies weak points. In a case study for a heavy-duty tool storage system:

– Simulated 150 lb dynamic loads revealed deflection in the drawer base. We reinforced the design with ribbing, reducing material fatigue failures by 40%.

3. Seamless Collaboration with Manufacturers

Exporting models to CNC machines or laser cutters eliminates manual measurement errors. One aerospace client saw a 15% reduction in scrap metal after switching to 3D-modeled cut files.

A Real-World Case Study: High-End Kitchen Drawers

Challenge: A luxury kitchen manufacturer needed drawers with integrated soft-close mechanisms and exact fit for irregular cabinet spaces.

Solution:

1. Scanned the cabinet interiors using 3D photogrammetry.

2. Modeled drawers with 0.5mm tolerance for seamless operation.

3. Rendered interactive prototypes for client sign-off, reducing approval time from 3 weeks to 4 days.

Results:

– 30% faster production cycle.

– Zero returns due to fit issues (previously 8% defect rate).

Expert Tips for Implementing 3D Models

🔍 Start with a template library: Save 20+ hours per project by reusing standard drawer profiles (e.g., undermount slides, dividers).

⚙️ Leverage cloud-based reviews: Tools like Onshape allow real-time client markups, avoiding email ping-pong.

💡 Validate with low-cost 3D prints: A $50 PLA prototype can expose assembly clashes before metal is cut.

The Future: AI and Generative Design

Emerging tools like Autodesk’s Generative Design can propose optimized drawer geometries based on weight distribution and cost constraints. In a test scenario, AI-generated designs reduced material use by 22% while maintaining strength.

Bottom line: 3D modeling isn’t just a design tool—it’s a competitive edge. By embracing it, you’ll slash costs, boost precision, and deliver systems that work flawlessly from the first install.

Need help implementing this? Share your toughest drawer design challenge in the comments—I’ll respond with tailored advice.