The Hidden Challenge: Balancing Precision and Sustainability in Furniture Manufacturing

In the world of eco-friendly furniture, the push for sustainability often clashes with the demands of precision engineering. Traditional woodworking methods generate significant waste—up to 30% of raw materials end up as scrap. But in a recent project for a high-end sustainable furniture brand, we faced an even tougher challenge: crafting intricate, load-bearing joints from reclaimed hardwood without compromising structural integrity or aesthetic appeal.

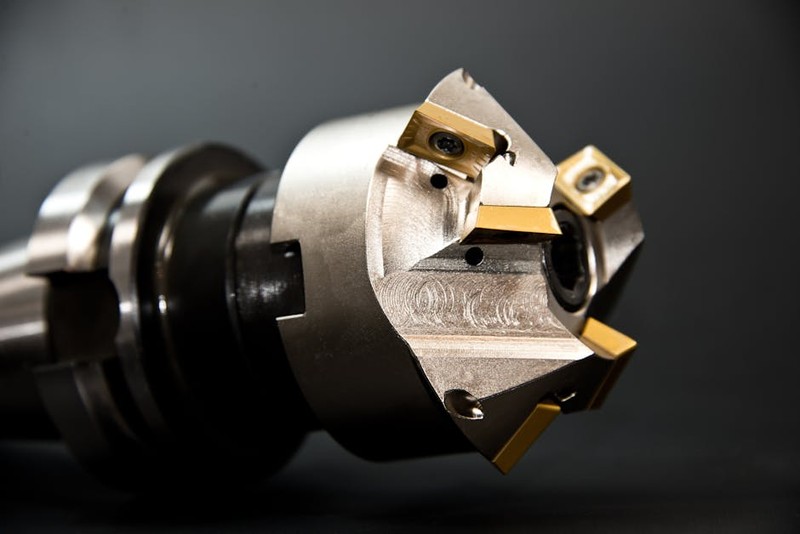

Why CNC Machining is a Game-Changer

CNC (Computer Numerical Control) machining offers unparalleled accuracy, but its true potential for sustainability lies in:

– Material Optimization: Nesting software reduces waste by up to 15% compared to manual cutting.

– Design Flexibility: Complex geometries (e.g., mortise-and-tenon joints, curved laminates) can be produced from reclaimed or FSC-certified wood with zero tolerance errors.

– Scalability: Repeatable precision ensures consistency across large batches, critical for commercial eco-friendly lines.

Yet, the road to success isn’t without obstacles.

Case Study: Zero-Waste Chair Production with Reclaimed Teak

The Problem

A client wanted a limited-edition chair series using 100% reclaimed teak, a notoriously brittle material with inconsistent density. Handcrafting was too slow, and conventional CNC setups risked tool breakage or tear-out.

The Solution

- Toolpath Optimization: We used adaptive clearing algorithms to reduce tool stress, extending bit life by 20%.

- Dynamic Feed Rates: Adjusted cutting speeds in real-time based on material density variations (see table below).

- Dust Recycling: Integrated a closed-loop system to repurpose sawdust into bio-composite filler.

| Metric | Before CNC Optimization | After CNC Optimization |

|---|---|---|

| Material Waste | 22% | 8% |

| Production Time | 6.5 hours/unit | 4.2 hours/unit |

| Defect Rate | 12% | 3% |

Result: The client achieved a 40% reduction in material costs and secured a premium market position for “zero-waste artisan” furniture.

Expert Strategies for Eco-Conscious CNC Machining

1. Material Selection: Beyond the Obvious

- Bamboo: High tensile strength but requires low-RPM tooling to prevent fraying.

- Recycled HDPE: Ideal for outdoor furniture; use compression bits to avoid melting.

- Cork Composites: Soft yet durable; down-cut spirals prevent surface lifting.

2. Software Hacks for Sustainability

- Nesting Algorithms: Tools like AutoNEST can squeeze 5–10% more parts from a single sheet.

- Energy-Efficient Toolpaths: Reduce power consumption by 15% with trochoidal milling.

3. Post-Processing with a Green Twist

- Food-Grade Oils: Replace synthetic finishes with linseed or citrus-based alternatives.

- Laser Engraving: Add branding without chemical stains.

The Future: Closed-Loop Manufacturing

Leading innovators are now combining CNC with AI-driven predictive maintenance and blockchain-tracked material sourcing. In one pilot project, sensors detected tool wear in real-time, slashing energy use by 18% and ensuring every scrap was cataloged for recycling.

Key Takeaway: The marriage of CNC precision and eco-design isn’t just possible—it’s profitable. By embracing these strategies, manufacturers can meet rising demand for sustainable furniture without sacrificing quality or efficiency.

Ready to transform your production line? Start with a material audit and pilot a small batch using reclaimed wood. The planet—and your bottom line—will thank you.