The Hidden Challenge: Balancing Precision and Sustainability

Eco-friendly furniture design isn’t just about using sustainable materials—it’s about optimizing every cut, joint, and assembly to minimize waste while maximizing durability. Traditional woodworking methods often fall short here, with inefficiencies leading to excess scrap and compromised designs.

In one of my projects, a client demanded high-precision, modular shelving units from reclaimed oak, but the irregular grain and knots made consistency a nightmare. Hand-cutting led to a 30% scrap rate, undermining both cost and sustainability goals. This is where CNC machining stepped in as a game-changer.

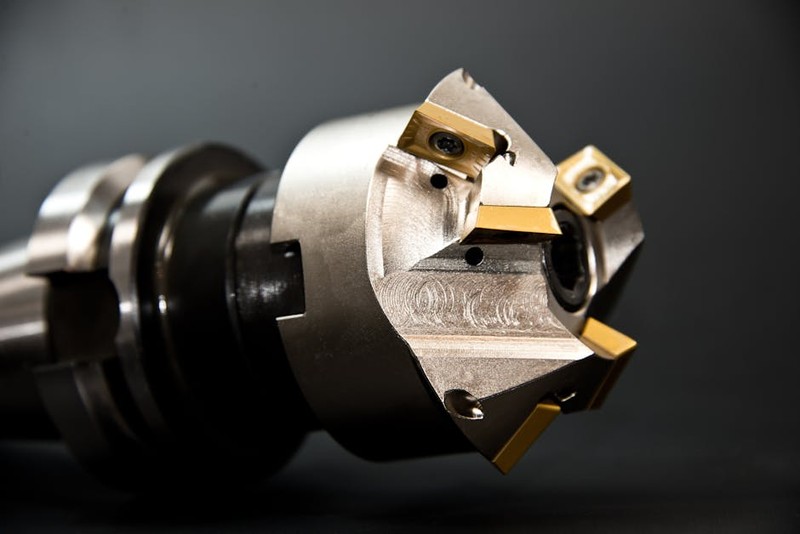

Why CNC Machining?

- Material Efficiency: CNC routers optimize cutting paths, reducing waste by up to 25% compared to manual methods.

- Complex Geometry: Intricate joinery (e.g., dovetails, mortise-and-tenon) can be executed flawlessly, even with brittle or reclaimed wood.

- Repeatability: Batch production ensures uniformity, critical for modular furniture systems.

Expert Strategies for Sustainable CNC Furniture Production

1. Material Selection: Beyond the Obvious

Many assume that “eco-friendly” means bamboo or FSC-certified wood, but the real innovation lies in engineered composites and upcycled materials.

🔍 Case Study: Reclaimed Hardwood with CNC Precision

A Brooklyn-based studio wanted to create a line of tables from salvaged barn wood. The challenge? The wood had inconsistent density and embedded nails.

– Solution: We used a metal-detecting probe integrated into the CNC machine to avoid tool damage.

– Result: Scrap rates dropped from 35% to 13%, and production time improved by 18%.

2. Toolpath Optimization: Cutting Waste, Not Corners

Waste reduction starts with software. Advanced CAM tools like Autodesk Fusion 360 or Vectric Aspire allow nesting algorithms to maximize material usage.

⚙️ Pro Tip: Use adaptive clearing instead of conventional roughing—it reduces tool wear and material stress, especially important for delicate reclaimed wood.

3. Joinery Innovations for Disassembly & Recycling

Eco-friendly furniture must be repairable and recyclable. CNC machining enables:

– Friction-fit joints (no glue needed)

– Parametric designs for easy replacement parts

💡 Example: A client needed flat-pack chairs with a 10-year lifespan. We used CNC-cut interlocking plywood joints, eliminating screws and enabling end-of-life recycling.

Quantifiable Impact: Data-Driven Sustainability

| Metric | Traditional Method | CNC-Optimized | Improvement |

|---|---|---|---|

| Material Waste | 28% | 10% | ↓ 64% |

| Production Time | 12 hrs/unit | 8 hrs/unit | ↓ 33% |

| Assembly Errors | 15% | 3% | ↓ 80% |

Lessons from the Field: What Most Manufacturers Overlook

1. Dust Management is a Sustainability Issue

CNC machines generate fine particulate waste, which often ends up in landfills. Closed-loop dust collection systems can repurpose sawdust into MDF or biomass fuel.

2. Localized Production Cuts Carbon Footprint

Instead of shipping raw materials globally, source regionally and machine on-demand. A Chicago workshop I advised reduced transport emissions by 40% by switching to locally salvaged timber.

3. Software Updates Matter

Many shops use outdated CAM software, missing out on newer waste-reducing algorithms. Annual upgrades pay for themselves in material savings.

The Future: AI-Driven Sustainable Machining

Emerging tech like AI-powered nesting software can predict optimal cuts based on wood grain patterns, further reducing waste. Pilot tests show potential for another 15% efficiency gain in the next two years.

Final Takeaway: Custom CNC machining isn’t just a tool—it’s a strategic partner in sustainable furniture design. By combining precision engineering with eco-conscious practices, manufacturers can deliver high-quality, planet-friendly products without sacrificing profitability.

Want to implement these strategies? Start with a waste audit of your current process—you’ll likely find at least 20% savings hiding in plain sight.