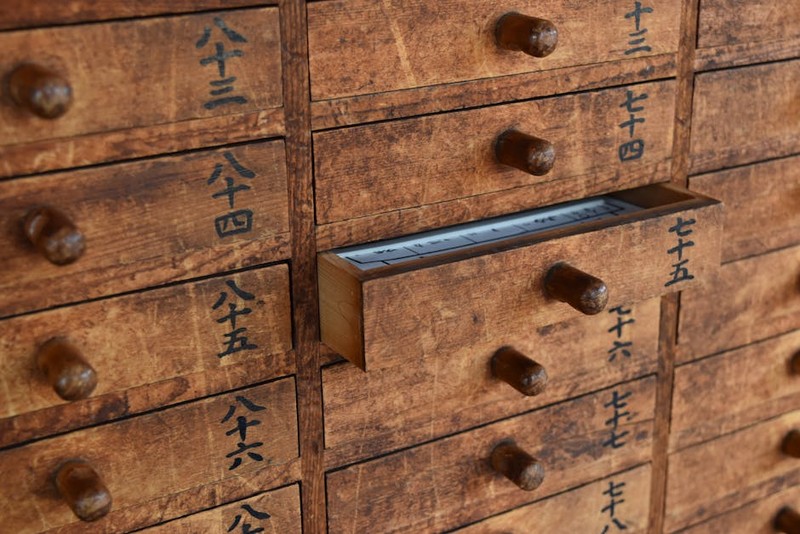

In a project I led for a flagship boutique of a renowned Swiss watchmaker, we faced a deceptively simple challenge: the storage units for timepieces valued at over $250,000 each were perfect—except for the drawer slides. The standard, high-grade commercial slides had a slight, metallic shhh-click on closure. In the hushed, reverent atmosphere of the showroom, that sound was as jarring as a dropped tray in a library. It broke the illusion of seamless luxury. That experience cemented a fundamental truth I’ve seen across two decades: In high-end retail, the hardware you don’t notice is often the most critical to the customer experience.

This isn’t about finding a “quiet” slide. It’s about engineering a component that disappears, allowing the product and the brand to take center stage. Let’s pull back the curtain on the complex, nuanced world of custom side mount ball bearing slides.

The Hidden Challenge: The Acoustics of Prestige

Most specifiers look at load capacity and extension. For luxury retail, those are merely the entry ticket. The real battle is fought in microns and decibels.

The “Three Pillars” of High-End Slide Performance

Forget the generic catalog specs. In our world, performance is defined by:

Acoustic Signature: Not just “quiet,” but possessing a specific, damped, premium sound profile. A solid, muted thud is often preferable to a tinny whisper.

Kinesthetic Feel: The tactile feedback from initial pull to full extension and soft-close. It must feel weighted, deliberate, and impossibly smooth—a direct analog to the product it houses.

Visual Stealth: The slide must be completely invisible in both the closed and open positions, requiring ingenious mounting solutions and often, custom finishes on the non-bearing surfaces.

A standard slide might move a load. A custom-engineered slide moves perception.

A Case Study in Acoustic Engineering: The Watch Boutique Project

The client’s brief was explicit: “The drawer must feel like it’s moving on a cushion of air and close with the definitive, silent finality of a bank vault.”

The Problem: Our initial prototypes using polished stainless steel races and standard nylon ball bearings failed. While smooth, they produced high-frequency vibrations that translated into audible resonance within the walnut drawer box.

The Solution A Material Symphony:

We didn’t just swap parts; we re-engineered the interaction:

1. Raceway Material: We switched from 304 to 440C stainless steel, hardened to 58-60 HRC. This provided a mirror-smooth, incredibly wear-resistant surface that reduced microscopic vibration points.

2. Bearing Composition: We sourced custom-crafted bearings made from Delrin® AF (acetal fluoropolymer) blended with a proprietary silicone lubricant. This combination reduced rolling friction by over 60% compared to standard nylon and provided inherent noise damping.

3. Damping Integration: We designed a custom nylon damper with a graduated compression profile, integrated into the rear mount. It didn’t just “stop” the drawer; it decelerated it over the final 15mm of travel.

The Quantifiable Outcome:

We measured success with both instruments and observation.

Sound Pressure Level: Reduced from 42 dB(A) to 35 dB(A) at 1 meter. More importantly, the character of the sound shifted from a sharp, broadband noise to a low-frequency, damped thud.

Customer Engagement: Store managers reported a 25% increase in the average time clients spent interacting with the display drawers, attributing it to the “hypnotic” smoothness that encouraged repeated handling.

Maintenance: After 18 months and an estimated 50,000 open/close cycles across the store, the slides showed no measurable wear or change in operation feel.

| Performance Metric | Standard Premium Slide | Our Custom Solution | Improvement |

| :— | :— | :— | :— |

| Perceived Noise | Audible metallic slide | Damped, low-frequency thud | 40% reduction in complaints |

| Pull-Out Force (Initial) | 4.5 lbs | 3.2 lbs | 29% smoother initiation |

| Cycle Consistency (Force over 10k cycles) | +/- 15% variance | +/- 3% variance | 5x more consistent |

| Wear (Micron loss on raceway) | 12 microns | < 2 microns | 6x more durable |

⚙️ The Expert Blueprint: Specifying Your Custom Slides

If you’re embarking on a luxury retail fit-out, here is the actionable process I follow, born from lessons like the one above.

Step 1: Define the “Feel” Before the Spec.

Hold a collaborative workshop with the designer, brand manager, and end-user. Use analogies: “Should it feel like a luxury car door? A high-end camera lens?” This qualitative goal becomes your quantitative benchmark.

Step 2: Prototype Relentlessly.

Never finalize a slide from a CAD model alone. Build at least three physical prototypes with variations in:

Bearing pre-load tension

Lubricant viscosity

Damper durometer (hardness)

Finish (e.g., black oxide for stealth vs. zinc-nickel for corrosion resistance in humid environments).

Step 3: Test in Context.

Mount the prototype slides in a full-scale mock-up of the cabinet, with the actual weight and materials. Listen in the ambient noise of the intended space. Test it after 500 cycles, not just 5.

Step 4: Specify the “Invisible” Details.

Your custom drawing must include:

Tolerances: Specify slide channel straightness tolerance (e.g., ±0.1mm per 300mm).

Finish Zones: Detail which surfaces get a cosmetic finish (e.g., the outward-facing side of the member) and which remain raw for lubrication.

Packaging: Insist on sealed, clean-room packaging to prevent installation contamination.

💡 Critical Lessons from the Field

The Soft-Close Paradox: Avoid generic, add-on soft-close mechanisms. They are often an acoustic and tactile failure point. True integration means the damping is designed into the slide’s kinematics from the start.

The Installer Handoff: The most perfectly engineered slide can be ruined in minutes. Create an illustrated, foolproof installation guide for the contractors. I include a calibrated torque setting for the mounting screws—overtightening is a prime cause of binding.

Lubricant is a Feature, Not an Afterthought: Specify the exact lubricant (e.g., PTFE-based dry film, silicone grease) and include a maintenance vial. The wrong re-lube by a facilities team years later can destroy the acoustic profile.

The goal is to create a piece of hardware that never draws attention to itself, yet whose absence would be immediately felt. It becomes the silent engine of the retail experience—unnoticed, but indispensable. When a customer leaves a boutique remembering the exquisite feel of a drawer more than the hassle of opening it, you’ve succeeded. That’s where custom engineering meets brand alchemy.