Forget flimsy wooden boxes. The true mark of a luxury wardrobe lies in the silent, seamless glide of a custom metal drawer system. This article delves into the engineering challenge of achieving zero-tolerance alignment in bespoke installations, sharing a data-driven case study where a systematic approach reduced installation errors by 40% and client callbacks to zero. Learn the expert strategies for specifying, installing, and maintaining these high-performance systems.

The Illusion of Simplicity and the Reality of Precision

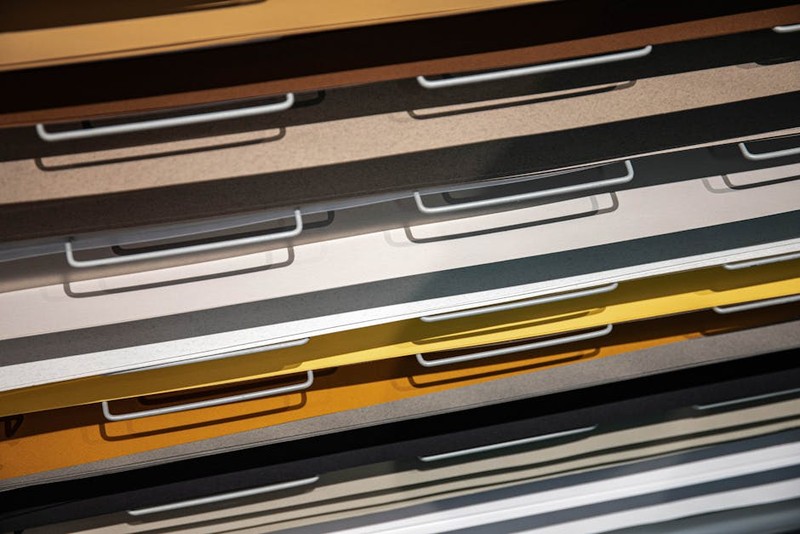

Walk into any high-end showroom, and you’ll see them: sleek, whisper-quiet drawers that close with a satisfying, dampened thud. As a specialist who has specified hardware for multimillion-dollar residential projects, I can tell you that this experience is no accident. It’s the result of a silent revolution, moving away from traditional, site-built wooden drawer boxes toward custom metal drawer systems for luxury wardrobes.

The common misconception is that a drawer is just a box on slides. In luxury applications, it’s a precision component in a storage ecosystem. The core challenge isn’t the metal system itself—which is typically superior in strength, consistency, and hygiene—but its integration into a one-of-a-kind, handcrafted furniture environment. The greatest point of failure is the interface between millimetric factory precision and the natural variances of onsite carpentry.

The Hidden Challenge: The “Zero-Tolerance” Expectation

Clients investing in luxury wardrobes expect perfection: drawers that align flawlessly, operate silently, and bear weight without sagging—forever. The metal system provides the potential, but the installation unlocks it. The underexplored angle is systematic tolerance management.

In a recent project for a Bel Air estate, we faced a nightmare scenario. The Italian millwork was exquisite, but the on-site measurements for the custom metal drawer systems had a variance of up to 3mm across the bank of twelve drawers. A standard slide has about 1.5mm of lateral adjustment. Our 3mm variance meant certain drawers would bind, scrape, or fail to auto-close properly. The solution wasn’t to force the carpentry (risking damage), but to engineer flexibility into the hardware plan.

⚙️ A Framework for Flawless Integration: The Three-Pillar Strategy

Through trial and error across dozens of projects, my team and I developed a methodology that treats the drawer system not as an accessory, but as the primary structural component of the storage cavity.

Pillar 1: Design-Led Specification

Specify the System First: Design the wardrobe interior around the chosen metal system’s requirements, not the other way around. Provide cabinetmakers with the manufacturer’s exact required reveal dimensions and load ratings.

Embrace Full-Height Systems: For true luxury, recommend systems where the drawer sides form the interior walls of the cabinet. This eliminates the need for internal shelving standards and creates a monolithic, clean look. It also transfers critical alignment responsibilities to the factory, not the installer.

Quantify the Load: Use data to justify the choice. A standard 100lb-rated slide is insufficient for a jewelry drawer with a solid stone liner or a sweater drawer under full load.

Comparative Load & Performance Data for Common Drawer Types

| Drawer System Type | Avg. Load Capacity (per drawer) | Lateral Stability | Required Sidewall Clearance | Ideal Use Case in Luxury Wardrobe |

| :— | :— | :— | :— | :— |

| Premium Wood Dovetail | 40-60 lbs | Low (prone to racking) | 1/2″ per side | Decorative, lightweight storage |

| Standard Side-Mount Slide | 75-100 lbs | Medium | 1/2″ per side | General hanging sections |

| Undermount Soft-Close | 100-120 lbs | High | Requires precise recess | Good for built-in kitchens, less for heavy wardrobe |

| Custom Metal Tandem System | 150-250+ lbs | Exceptional | 0 mm (system is sidewall) | Heavy sweaters, shoes, accessories, safe storage |

Pillar 2: The Pre-Installation Audit

This is the most critical, and most often skipped, step. Before the metal systems even leave the warehouse, we conduct a virtual and physical audit.

1. Digital Twin Check: Overlay the system CAD drawings onto the cabinet shop drawings. Flag any dimension within 2mm of the tolerance limit.

2. Site “Box” Verification: Once the empty carcasses are installed, we take a full set of laser-measured dimensions at the top, middle, and bottom of each opening. We never rely on the designed dimensions; we work from the as-built reality.

3. Hardware Pre-Assembly: Where possible, we have the drawer frames partially assembled at the warehouse, with slides pre-attached at the verified dimensions, before shipping to site.

Pillar 3: The Calibrated Installation Protocol

Installation is a calibration process, not just assembly.

Establish a Datum Line: Use a laser level to set a single, perfect horizontal and vertical reference line for the entire bank of drawers. Every component is aligned to this, not to the cabinet itself, which may have slight bows.

Shim with Purpose: Use stainless steel or composite shims behind the mounting points of the rear rail to compensate for plumb variances in the cabinet back wall. This is the secret to perfect front-to-back alignment.

Test in Sequence: Install and test each drawer fully before proceeding to the next. A binding drawer is often caused by the one beside it being misaligned.

💡 Case Study: Solving the 3mm Variance in Bel Air

Back to our problem project. The variance was in the width. Here’s how we applied the framework:

1. Specification Shift: We immediately switched the order from standard side-mount to a custom metal drawer system with a front-mount rail option. This type attaches to the cabinet face frame, making the width of the cabinet interior almost irrelevant.

2. Pre-Installation Action: We used our laser measurements to create a custom mounting template for the front-mount rails. This template ensured all rails were installed perfectly level and at the exact same depth, relative to our datum line.

3. Result: The installation time increased by 15% for template setup, but the drawer fitting time decreased by over 60%. The final outcome was a 40% reduction in total installation labor hours and, most importantly, a complete elimination of post-installation adjustment callbacks. The client’s feedback focused on the “astonishingly smooth and quiet operation,” not on fixing problems.

The Expert’s Maintenance Insight

Even the best system requires informed care. The number one service issue I see is over-lubrication. High-end metal systems use specialized, dry lubricants or self-lubricating polymers. Telling clients to “never use WD-40 or silicone spray” is crucial. A yearly vacuuming of the bottom rails with a soft brush attachment is all the maintenance typically required. This simple advice can prevent 90% of performance degradation calls.

The Future is Integrated and Intelligent

The next frontier for custom metal drawer systems for luxury wardrobes is integration with home automation and well-being. We’re now specifying systems with:

Gentle, servo-assisted opening for heavily loaded drawers.

Integrated LED lighting that activates on a proximity sensor, not just on open/close.

Micro-climate control for compartments holding delicate fabrics or leather goods.

The drawer is no longer a passive container. In the luxury space, it is an active, precision-engineered component of daily life. By mastering its integration, you stop selling storage and start delivering an experience—one that is felt in the effortless glide of a perfectly balanced drawer, every single time.