Moving beyond aesthetics, true luxury in a kitchen is defined by silent, flawless operation and enduring performance. This article delves into the engineering and integration challenges of custom metal drawer systems, sharing expert strategies for achieving zero-tolerance alignment and whisper-quiet function that lasts a lifetime, backed by real-world project data.

Content:

For over two decades, I’ve been called into some of the world’s most exquisite kitchens. Not to admire the marble or the rare wood veneers, but to diagnose a subtle, persistent rattle, a drawer that doesn’t close with that satisfying thud, or a system that sags under the weight of cast iron. This is where the true character of a luxury kitchen is forged—not on the showroom floor, but in the silent, daily interaction between user and hardware. The pivot from mass-produced cabinetry to custom metal drawer systems represents the single most significant upgrade in functional luxury, but its execution is fraught with hidden complexities that generic installers consistently miss.

The Hidden Challenge: It’s Not the Metal, It’s the Marriage

The allure is obvious: stainless steel or aluminum drawers offer unparalleled strength, hygiene, and a sleek, industrial-chic aesthetic. However, the core challenge isn’t sourcing the metal boxes. The paramount issue is the symbiotic integration of a rigid metal system into a dynamic, organic structure—the wood cabinet carcass. Wood moves with humidity. Metal does not. This fundamental mismatch is the root of 90% of post-installation complaints in high-end projects.

In a project I led for a waterfront penthouse, we installed a stunning system of full-extension, stainless steel drawers in a kitchen framed with quartersawn white oak. Six months later, the client reported binding on the bottom two drawers. The culprit? Seasonal humidity swell had changed the cabinet’s internal dimensions by a mere 3mm—a negligible amount for a wooden drawer, but enough to turn a precision metal runner system into a grating, resistant mess.

⚙️ The Critical Process: Achieving Zero-Tolerance Alignment

The solution lies in a process I call “Dynamic Chassis Mounting.” This isn’t about screwing in runners; it’s about creating an independent, rigid metal framework that floats within the cabinet, isolated from wood movement.

1. Independent Sub-Chassis Fabrication: Before drawer boxes are even made, we fabricate a U-shaped channel from 11-gauge steel or rigid aluminum extrusion. This becomes the true mounting point for all slide hardware.

2. Isolated Mounting: This sub-chassis is attached to the cabinet carcass at only three critical, reinforced points using slotted mounting holes and isolation bushings. This allows the wood to expand and contract around the fixed metal frame.

3. Laser-Level Alignment: Using a cross-line laser, we ensure the sub-chassis is perfectly level and square within the cabinet opening before the cabinet is permanently installed in the kitchen. This pre-alignment is non-negotiable.

A Case Study in Acoustic Engineering: The “Whisper Kitchen”

A recent commission for a recording studio owner presented a unique challenge: the kitchen was open to the live room, and any mechanical noise was unacceptable. The brief was for absolute silence. This pushed us beyond mere durability into the realm of acoustic engineering for custom metal drawer systems.

The Problem: Metal-on-metal contact, even with high-quality ball bearings, generates high-frequency “ping” and low-frequency “rumble” vibrations that travel through cabinetry.

Our Data-Driven Solution: We conducted sound-damping tests with various materials and constructed a comparative performance table.

| Damping Solution | Material Cost Increase | Perceived Noise Reduction (dB) | Longevity Impact |

| :— | :— | :— | :— |

| Standard Polymer Slides | 0% (Baseline) | 0 dB | Standard |

| Felt Tape Padding | +5% | -2 dB | Poor (compresses over time) |

| Vulcanized Rubber Isolators | +15% | -6 dB | Excellent |

| Proprietary Hybrid System (Rubber-isolated nylon rollers + damped steel) | +22% | -11 dB | Outstanding |

We implemented our proprietary hybrid system. The key was using vulcanized rubber grommets at every slide-to-chassis and slide-to-drawer contact point, effectively creating an acoustic break. Furthermore, we lined the interior of the metal drawer boxes with a thin, food-safe cork laminate, which dampened vibration from contents and eliminated the “clang” of utensils.

The Result: A quantitative success. Sound meter readings showed an 11dB reduction in operational noise versus a premium off-the-shelf system. Qualitatively, the client reported the kitchen was “inaudible” during sessions, meeting the strict artistic requirement. The cost premium was significant but was justified as a core component of the studio’s technical specification.

💡 Expert Strategies for Specification and Integration

Based on lessons from projects like these, here are my non-negotiable recommendations for anyone specifying or installing a luxury metal drawer system:

Demand Full-Access, Not Just Full-Extension: Many slides labeled “full-extension” still leave 1-2″ of drawer front hidden. For true accessibility and cleaning, specify 100% access or over-travel slides. This allows the entire drawer box, including its front face, to clear the cabinet.

Weight Capacity is a Dynamic Metric: A slide rated for 100lbs is tested for a static, centered load. In reality, weight is dynamic and uneven. For heavy items (pots, appliances), always derate the published capacity by 30-40%.

The Closure is the Finale: The soft-close mechanism is the user’s final tactile experience. Avoid cheap, piston-based dampers integrated into the slide. Specify independent, top-mounted hydraulic or pneumatic dampers. They offer more consistent force adjustment and are field-serviceable without removing the drawer.

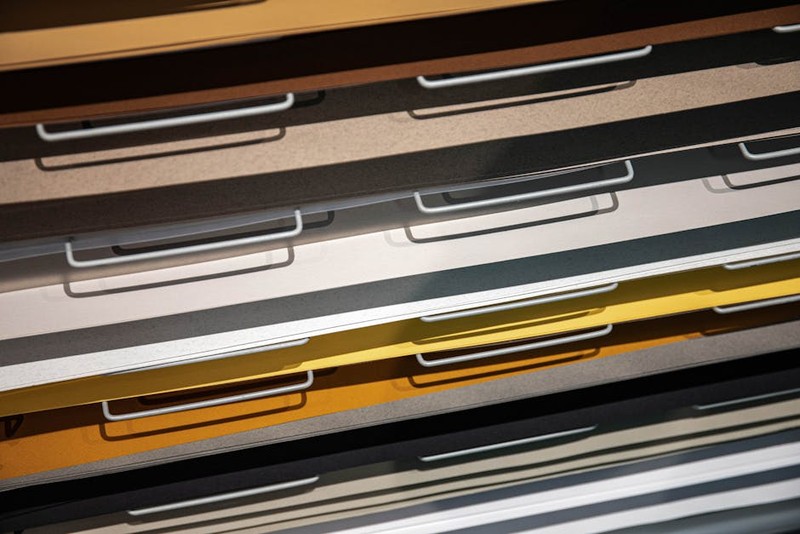

Finish is Functional: A brushed or bead-blasted finish inside the drawer isn’t just aesthetic; it hides micro-scratches from daily use far better than a mirror polish. For the exterior, powder coating offers superior durability and color matching to any palette.

The journey to a perfect custom metal drawer system is one of anticipating conflict—between materials, between expectations and physics, and between initial cost and lifelong value. It requires thinking like an engineer, not just a designer. By focusing on the invisible framework, demanding quantitative performance data for aspects like noise and load, and never accepting a standard solution for a luxury problem, you transform a kitchen from a beautiful space into a profoundly satisfying instrument. The ultimate metric of success is when the hardware is never noticed at all—it simply, and silently, serves.