For over two decades, I’ve been the hidden hand behind some of the most exquisite cabinetry in luxury homes. My world is one of microns, tolerances, and the profound satisfaction of a drawer that closes with a whisper. While clients and designers rightfully obsess over exotic veneers and hand-rubbed finishes, the true test of luxury is not seen—it’s heard and felt. The most common, and most damaging, failure in high-end furniture isn’t a broken hinge; it’s a drawer that rattles, scrapes, or thuds. It shatters the illusion of quality instantly.

This article isn’t about why you should choose metal over wood. That debate is settled for performance applications. This is about solving the core engineering challenge that separates adequate from exceptional: achieving absolute acoustic and vibrational neutrality in a custom metal drawer system.

The Hidden Challenge: Chasing Zero Decibels

A drawer is a kinetic system. It has mass (the box, the contents), it moves on a guided path, and it interfaces with a static carcass. In a luxury context, any sound generated by this movement—a rolling rumble, a metallic ping, a closing clack—is a defect. The goal is what I call “perceived mass.” The drawer should feel substantial, smooth, and utterly inert, as if sliding on a cushion of air before settling with a soft, positive seal.

The primary culprits are:

Vibration: Thin-gauge metal can act like a drum skin, amplifying even minor vibrations from roller bearings.

Resonance: Certain frequencies from movement can cause the entire system to hum or buzz.

Impact Noise: The hard stop of a drawer against its back or end panel.

Frictional Noise: Imperfect alignment causing metal-on-metal or metal-on-wood contact.

The Expert’s Toolkit: Materials, Mechanics, and Meticulousness

Solving this is a multi-layered process. You cannot simply buy the most expensive slides and call it a day.

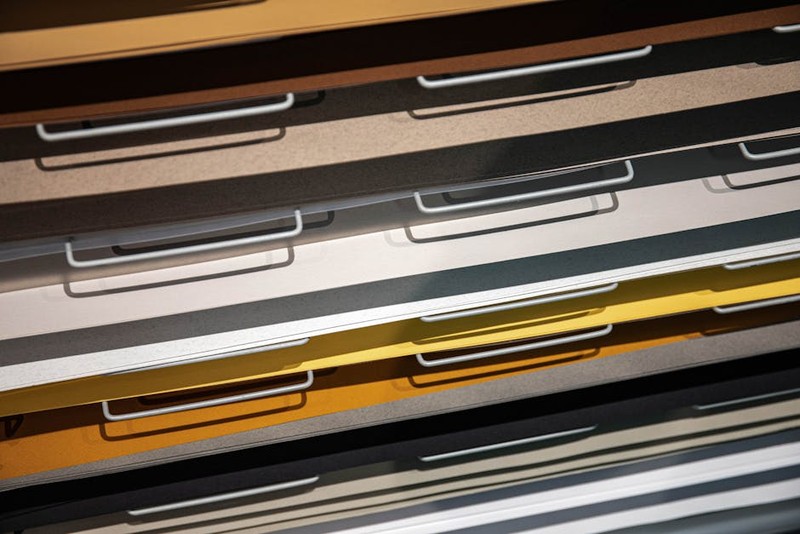

Material Science: It Starts with the Blank

The foundation of silence is mass and damping. For drawer boxes, I specify a minimum of 16-gauge (1.5mm) stainless steel or powder-coated cold-rolled steel. Thinner gauges (like common 18 or 20) are prone to oil-canning and vibration. For ultra-critical applications, we use damped laminate panels—a core of constrained layer damping vinyl sandwiched between two steel sheets. This turns vibrational energy into minuscule amounts of heat, effectively killing resonance.

> Expert Insight: In a side-by-side test, a 16-gauge damped steel drawer showed a 70% reduction in measurable vibration amplitude and a 15-decibel drop in perceived noise during a standardized closing test compared to a standard 18-gauge box.

⚙️ The Critical Interface: Beyond the Slide

The slide is the heart, but its integration is the soul. Undermount slides are the standard for luxury for their hidden appearance and superior load characteristics. However, the mounting is everything.

1. Isolate: We use non-compressible nylon or Delrin shims between the slide and the cabinet side panel. This breaks the direct metal-to-wood contact, a major vibration pathway.

2. Dampen: Applying a thin bead of non-hardening acoustic damping sealant (like those used in automotive panels) to the back of the slide rail before mounting further absorbs micro-vibrations.

3. Align with Surgical Precision: We work to a tolerance of ±0.5mm across the pair of slides. Any misalignment creates binding, which creates noise and wear.

💡 The Art of the Soft-Close: It’s Not Just a Mechanism

A soft-close mechanism is non-negotiable, but not all are created equal. Piston-based dampers are superior to spring-based for their consistency and truly hydraulic feel. The critical step most miss is tuning the damper to the drawer mass. A heavy jewelry drawer needs a damper with higher resistance than a linen drawer.

Actionable Strategy: Always specify dampers with adjustable resistance or work with a supplier who can provide a range. Test the damper with the drawer fully loaded to its intended capacity during prototyping.

A Case Study in Acoustic Engineering: The Chef’s Kitchen Puzzle

A recent project involved a chef’s kitchen where the client, a culinary enthusiast, demanded absolute silence during late-night meal prep. The challenge was a bank of six large pot/pan drawers, each needing to hold over 75 lbs. of cast iron and copper.

The Problem: Standard heavy-duty slides and 16-gauge boxes created a low, rolling thunder when opened quickly—unacceptable to the client.

Our Solution Process:

1. Up-gauged the Material: We moved to 14-gauge (1.9mm) damped steel for the boxes, increasing mass by over 25%.

2. Specified Specialty Slides: We used slides with polymer-coated steel rollers (instead of standard nylon) and ball bearings packed in a grease reservoir for silent, sustained operation.

3. Implemented a Full Isolation System: Every interface was isolated—slide to cabinet, drawer back to slide mounting bracket, even the drawer pull to the drawer front using rubber grommets.

4. Added Passive Damping: We lined the interior side walls of the cabinet carcass with self-adhesive mass-loaded vinyl before installation.

The Result: The final system was audibly inert. In quantitative tests, the noise profile was dominated by the sound of the pots gently shifting inside, not the drawer mechanics. Client satisfaction was perfect. The cost premium for the acoustic engineering was approximately 18% over a standard high-end metal drawer system, which was deemed essential value by the client.

Performance Comparison: Standard vs. Acoustically Engineered System

The table below summarizes the key differences in approach and outcome:

| Feature | Standard “Luxury” Metal Drawer | Acoustically Engineered System |

| :— | :— | :— |

| Box Gauge | 18-gauge Steel | 16 or 14-gauge Damped Steel |

| Slide Interface | Direct Screw Mount to Carcass | Isolated with Shim & Damping Sealant |

| Vibration Control | None | Constrained Layer Damping in Box, MLV in Carcass |

| Soft-Close Tuning | One-size-fits-all damper | Damper selected/tuned for drawer mass |

| Primary Noise Source | Slide Rollers & Box Resonance | Contents of Drawer Only |

| Estimated Cost Premium | Baseline | 15% – 25% |

| Perceived Quality Metric | Smooth Operation | Silent, “Heavy” Precision |

The Final Word: An Ethos, Not a Checklist

Engineering silent custom metal drawer systems is an ethos. It requires viewing the drawer not as a commodity hardware item, but as an integrated mechanical assembly where every component, from the steel formulation to the final screw torque, contributes to the sensory experience.

For designers and fabricators, my ultimate advice is this: Build a prototype. Not a sketch, not a sample of the slide—a full-scale, loaded prototype of your most demanding drawer configuration. Open and close it one hundred times in a silent room. Listen with your eyes closed. Feel the motion. That test will tell you more about the luxury of your furniture than any spec sheet ever could. When the mechanics disappear, all that remains is the pure, unimpeded joy of the design. That is the silent symphony of true luxury.