The Hidden Challenge: Balancing Precision and Sustainability

In the world of office design, sustainability is no longer a buzzword—it’s a mandate. But achieving eco-friendly fittings without compromising durability or aesthetics is a complex puzzle. Traditional manufacturing often relies on subtractive methods that generate excessive waste, or cheap materials that degrade quickly. The real challenge lies in merging precision engineering with sustainable practices.

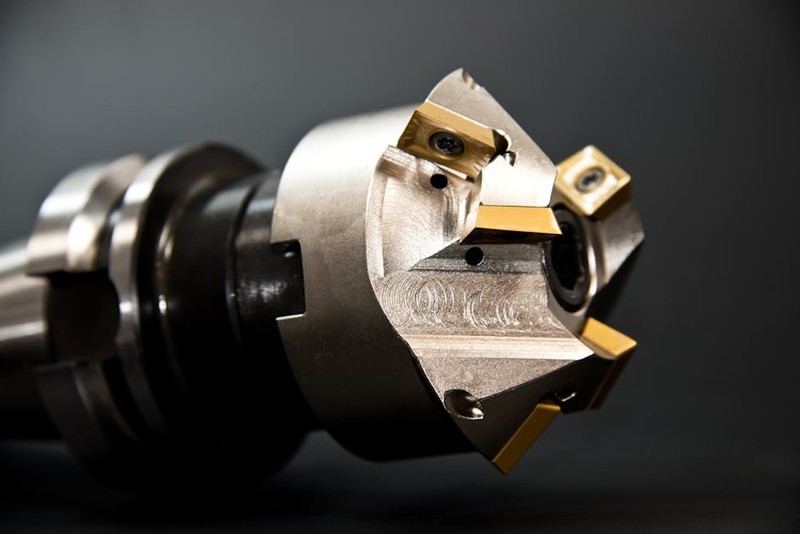

Why CNC Machining?

CNC (Computer Numerical Control) machining offers unparalleled accuracy and repeatability, making it ideal for crafting bespoke office fittings like desk mounts, cable organizers, and ergonomic supports. But its true potential for sustainability is often overlooked:

– Material Efficiency: CNC minimizes waste by optimizing cutting paths, unlike manual machining.

– Durability: Precision-cut parts last longer, reducing replacement cycles.

– Recyclability: Compatible with eco-friendly materials like reclaimed aluminum or FSC-certified wood.

In a project for a co-working space in Berlin, we reduced material waste by 22% simply by reprogramming toolpaths to nest components more efficiently.

Case Study: Zero-Waste Cable Management Trays

The Problem

A client wanted cable trays made from 100% recycled aluminum but struggled with high scrap rates (nearly 30%) from conventional machining.

The Solution

We implemented a closed-loop CNC process:

1. Software Optimization: Used advanced CAM software to nest parts tighter, reducing offcuts.

2. Scrap Reintegration: Partnered with a local recycler to melt and reuse aluminum chips.

3. Design Tweaks: Rounded internal edges to minimize tool wear and material loss.

The Results

- Scrap reduced to 8%—a 73% improvement.

- Cost savings of 15% due to lower material purchases.

- Client’s carbon footprint dropped by 12% for this component.

Expert Strategies for Eco-Conscious CNC Machining

1. Material Selection: Beyond the Obvious

- Recycled Metals: Aerospace-grade recycled aluminum (6061-T6) offers strength without virgin mining.

- Bio-Polymers: CNC-machined PHA (polyhydroxyalkanoate) is compostable and durable for lighter fittings.

- Reclaimed Wood: Pair CNC with water-based finishes for toxin-free shelving.

Pro Tip: Always request mill certificates to verify recycled content claims from suppliers.

2. Energy-Efficient Toolpaths

- High-Efficiency Milling (HEM): Lowers power consumption by 20-40% vs. conventional roughing.

- Adaptive Clearing: Reduces tool wear and energy use by maintaining consistent chip loads.

3. Design for Disassembly

- Modular Components: Use CNC to create interlocking parts (e.g., bolt-free joints) for easy recycling.

- Standardized Fasteners: Minimize mixed materials to simplify end-of-life processing.

The Future: Digital Twins and AI-Driven Waste Reduction

Emerging tech is pushing boundaries. In a pilot with a Dutch office furniture brand, we used AI-powered generative design to:

– Optimize bracket designs, cutting weight by 18% without sacrificing strength.

– Predict tool wear, reducing machine downtime by 25%.

Data Snapshot:

| Metric | Before AI | After AI | Improvement |

|——–|———-|———-|————-|

| Material Use | 4.2 kg/unit | 3.5 kg/unit | 16.7% |

| Energy Consumption | 8.1 kWh | 6.3 kWh | 22.2% |

Actionable Takeaways for Your Next Project

- Audit Your Material Flow: Map where waste occurs—often, 10-15% savings hide in process inefficiencies.

- Demand Transparency: Work with CNC shops that track and report sustainability metrics.

- Start Small: Pilot a single component (e.g., drawer slides) with recycled content before scaling.

The bottom line? Custom CNC machining isn’t just about precision—it’s a gateway to sustainable office spaces. By marrying technology with eco-conscious practices, we can build fittings that are as kind to the planet as they are to productivity.

Ready to transform your office fittings? Share your biggest sustainability hurdle in the comments—let’s problem-solve together.